A humanoid robot is a robot designed with a human-like body structure and capabilities, enabling it to operate in environments built for people without significant modification.

As global labor shortages intensify and traditional automation approaches reach their limits, manufacturers are increasingly exploring humanoid robots as a potential solution. Shaped like humans and built to work where humans do, humanoid robots are often presented as the next breakthrough in industrial automation.

But beyond the headlines and demonstrations, a more practical question emerges: what can humanoid robots realistically deliver today in real-world manufacturing and industrial environments?

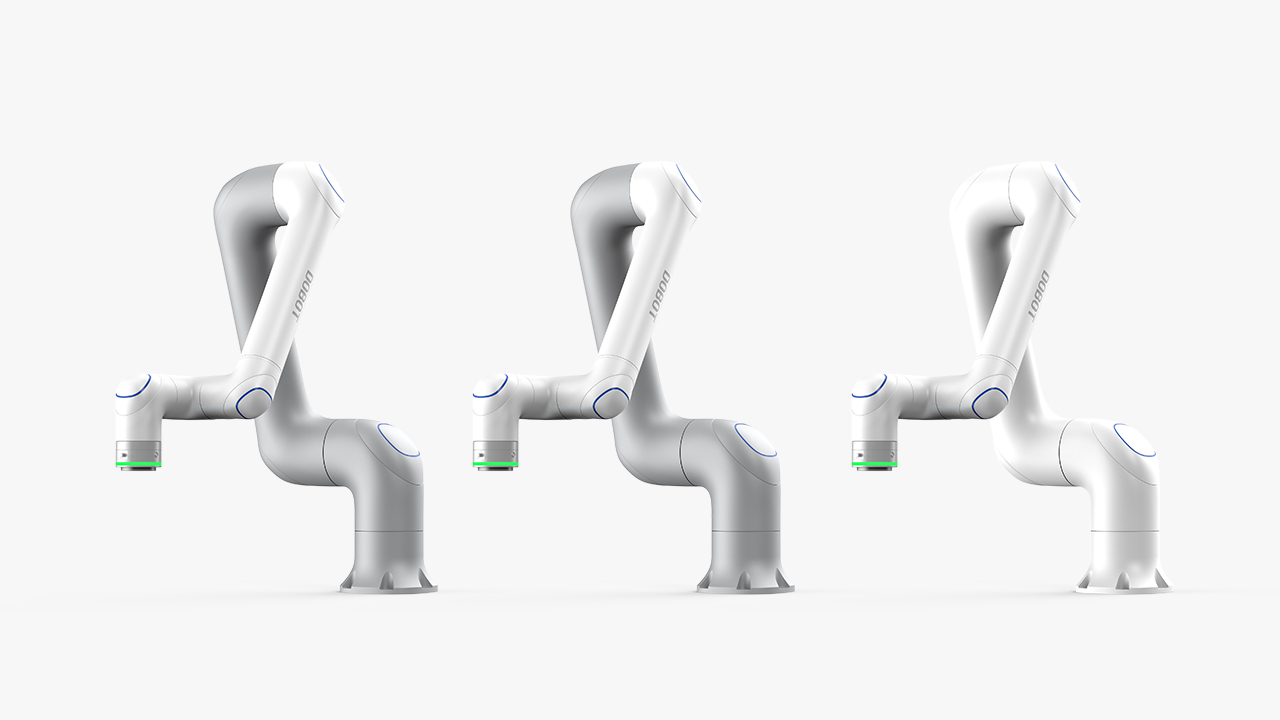

DOBOT Atom Worked in Cross-Scenario Multi-task Industrial Application

What Makes a Robot Humanoid? Key Characteristics and Definition

To answer the question “what is a humanoid robot” more precisely, industry organizations provide a formal definition. According to the International Federation of Robotics (IFR), it is defined as “a robot with human-like aesthetic appearance…capable of performing tasks in an environment designed for humans without the need to adapt it.” This core definition highlights their ultimate purpose: to integrate into our world as we have built it.

This potential stems from three key characteristics that set them apart:

- Human-Like Form: Bipedal Structure, Arms, and Hands: The familiar two-armed, two-legged design is not merely aesthetic. It is functional, allowing the robot to intuitively use human tools, navigate staircases, operate machinery, and work within spaces scaled for people, minimizing the need for costly environmental retrofits.

- Whole-Body Coordination and High Degrees of Freedom (DoF): True utility requires more than just a human shape; it demands the sophisticated orchestration of that form. This is achieved through a high number of degrees of freedom (DoF) – essentially, the robot’s movable joints. For instance, advanced models feature 41 degrees of freedom and bionic hands, enabling human-like dexterity and the precise, coordinated motion necessary for complex, unstructured tasks.

- Advanced Perception and Embodied AI for Autonomous Action: To move and act autonomously, these robots must perceive and understand their environment. This is powered by embodied AI and sensor fusion—combining human-like stereo vision, touch, and auditory sensing with substantial on-device computing power (e.g., 1500 TOPS). Architectures like transformer-based models process this data in real-time, enabling capabilities such as autonomous manipulation across 28+ DoF and learning from demonstration, shifting the paradigm from extensive pre-programming to adaptive, data-driven intelligence.

DOBOT Atom Performing Human-style Manipulation Tasks alongside VR-trained Operators

Finding Its Place: The Humanoid in the Industrial Automation Spectrum

To understand its practical role, we must see where the humanoid robot fits within the existing toolkit of industrial automation. The choice is never about one being universally “better,” but about selecting the right tool for the specific task and environment. The following comparison clarifies these distinct roles:

Humanoid Robots vs. Traditional Industrial Robots: Where Do They Fit?

| Dimension |

Traditional Industrial Robots |

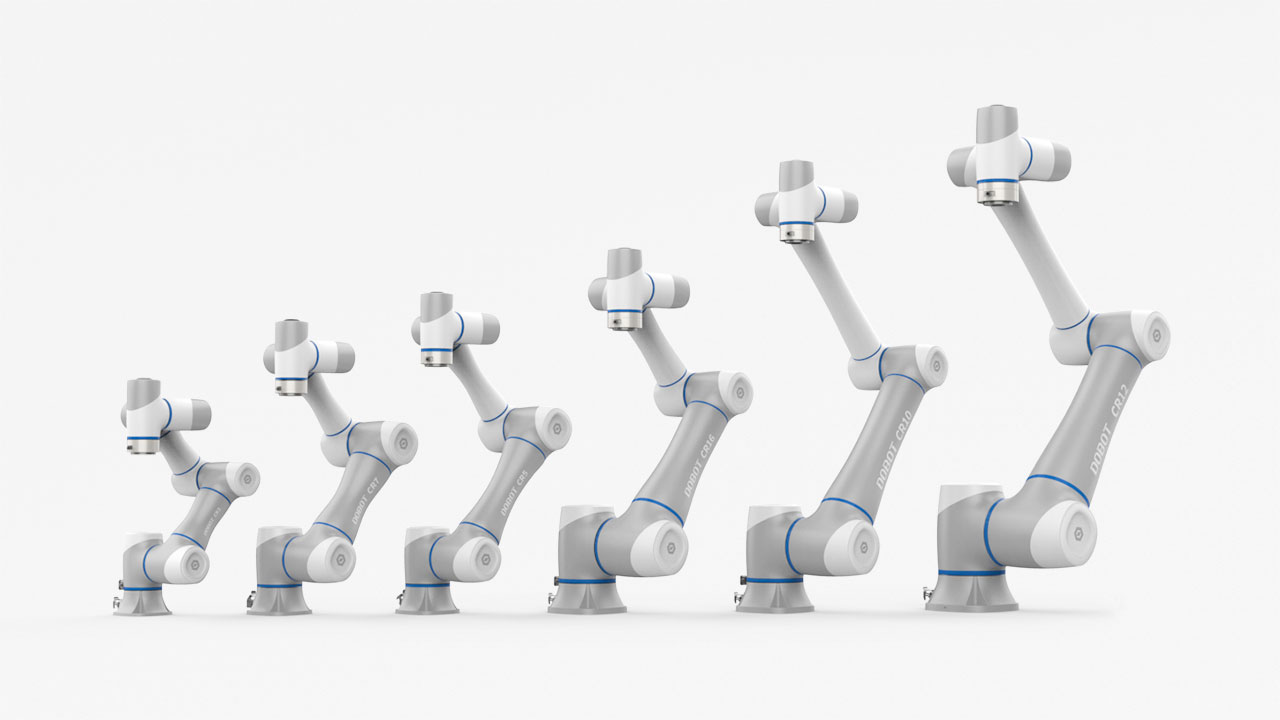

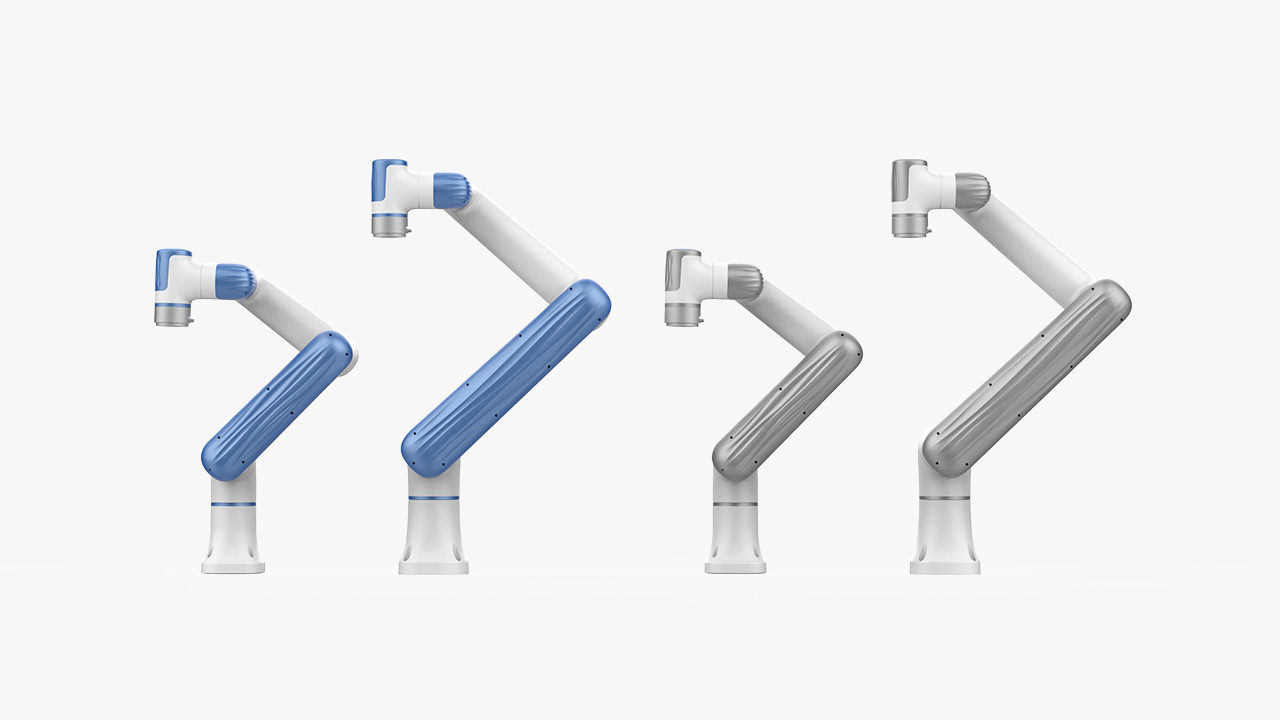

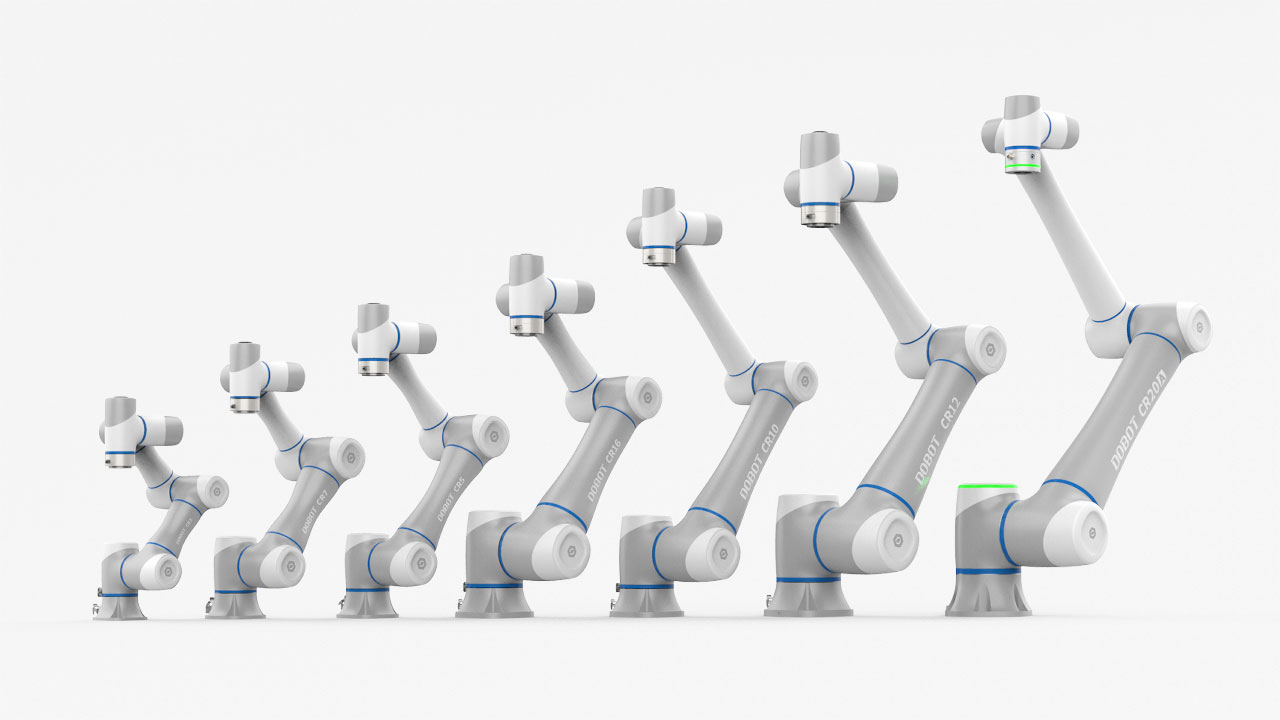

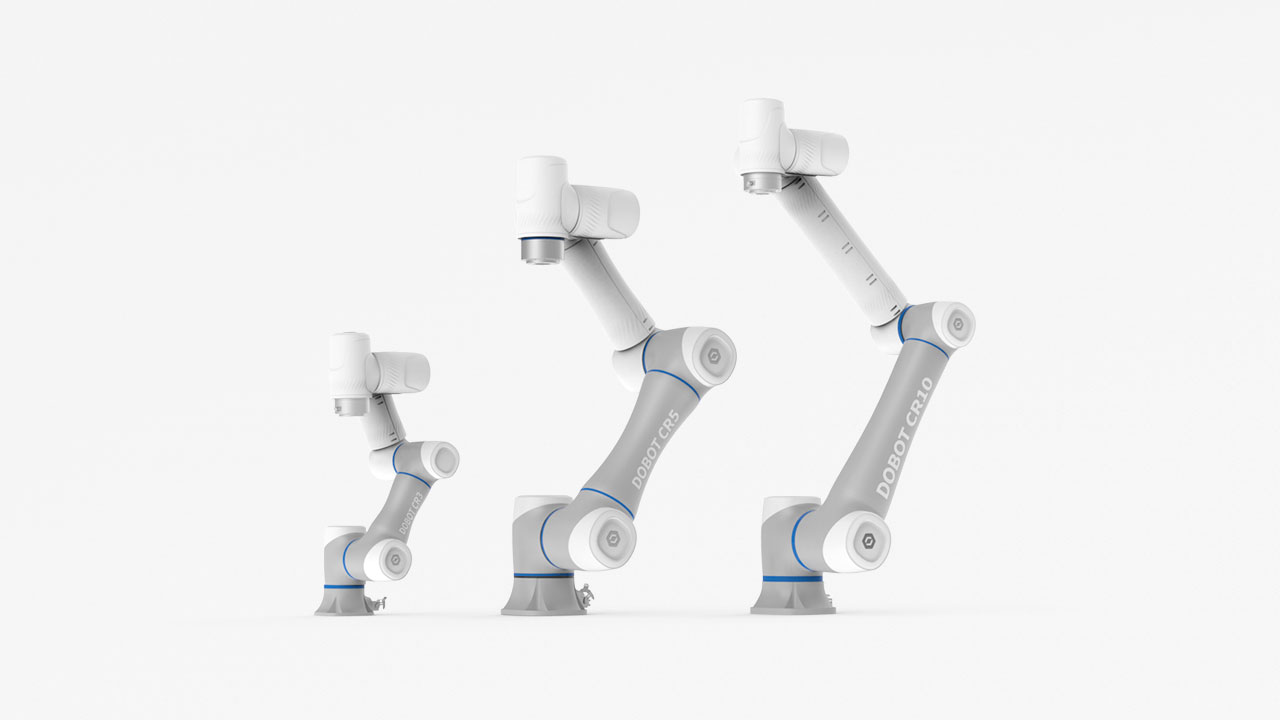

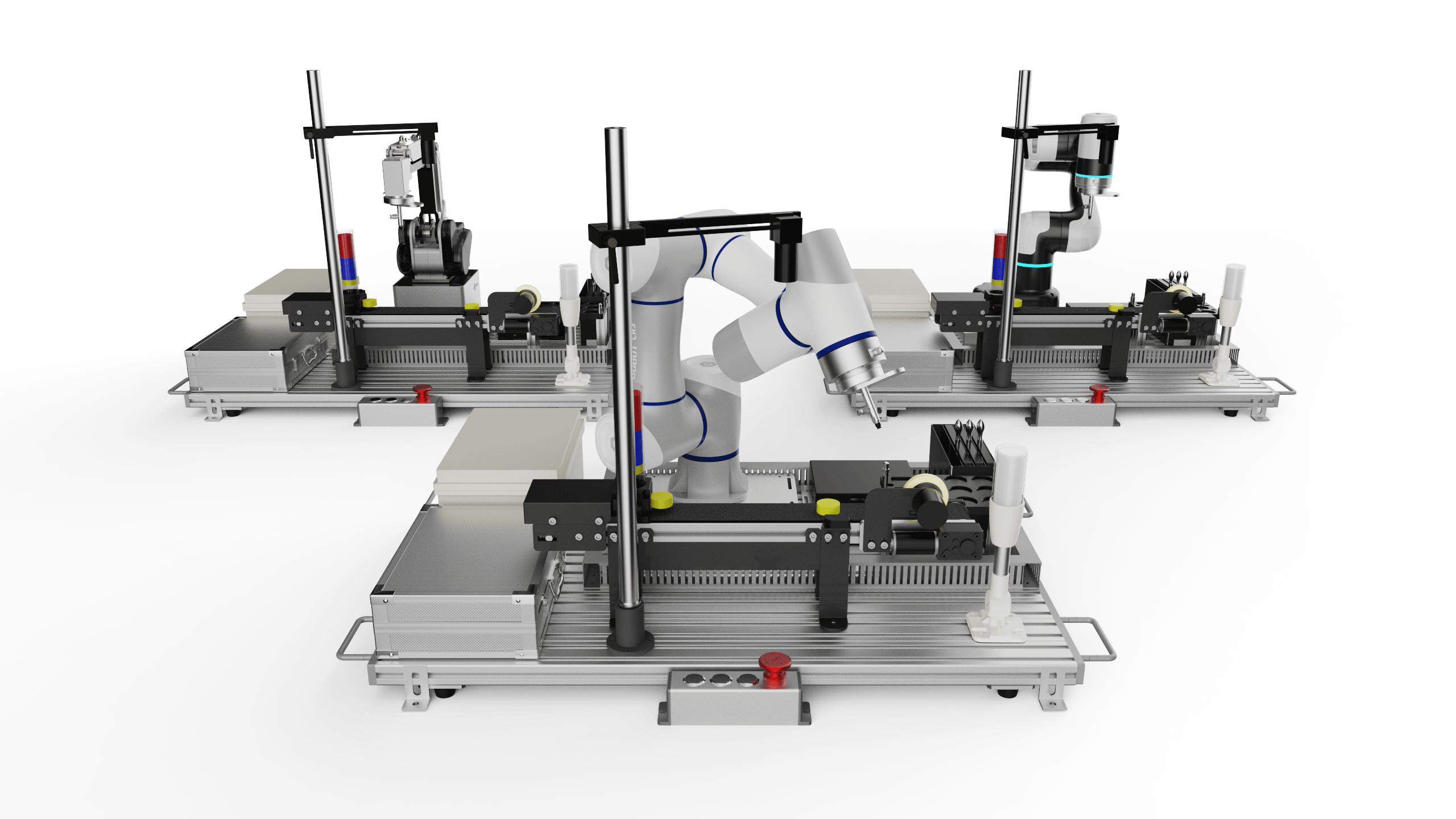

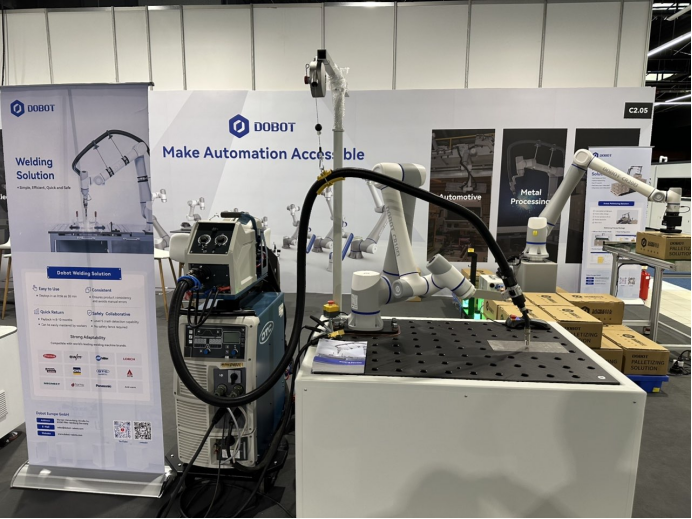

Advanced Robotics (CRs / CRSs) |

Humanoid Robots (ATOM / ATOM-Max) |

| Key Strength |

Extreme precision, high speed, heavy payload |

Flexibility, easy redeployment, safe collaboration |

Environmental universality potential for task generalization |

| Typical Environment |

Structured, caged, fixed stations |

Semi-structured, dynamically changing layouts |

Unstructured, human-designed spaces not retrofitted for automation (e.g., existing assembly lines, complex logistics hubs) |

| Primary Role Today |

The core workhorse for high-volume, repetitive processes |

A versatile supplement for enhancing flexibility and efficiency |

Frontier exploration & pilot testing in specific, complex industrial scenarios |

Bridging the Gap: Potential vs. Practicality Today

Recent engineering demos are undeniably impressive. Advances in control algorithms and hardware have enabled humanoid robots to walk on uneven terrain and perform basic manipulation tasks—clear proof that a human-shaped machine can move and interact in our world.

Yet translating these demonstrations into industrial value remains challenging. According to the International Federation of Robotics (IFR), key barriers include the lack of mass production, limited battery endurance for full-shift operation, and safety risks related to balance and stability in dynamic factory environments.

Taken together, these challenges reveal a central reality: the bottleneck is no longer technological feasibility, but economic and operational viability. Success in a lab does not automatically translate to ROI on the factory floor. The field is therefore shifting from showcasing what is possible to validating what is valuable.

Ultimately, understanding what a humanoid robot is—and what it is not—is essential for making informed automation decisions.

Looking Ahead: From Demonstration to Validation

Consequently, the narrative is decisively shifting. The question is no longer “Can it be built?” but “Where does it pay off?” This marks the industry’s necessary transition from a demonstration phase to a rigorous validation phase.

The path forward is pragmatic: success will be defined not by the most human-like gait, but by the clearest ROI in a specific application. For manufacturers, this translates to a strategy of targeted exploration—identifying those unique, high-impact problems where a humanoid’s form is a fundamental advantage, and engaging in structured pilot programs to measure its real-world value.

The next chapter of automation will be written by those who couple visionary potential with operational rigor. It begins with a single, well-defined question: “What is the most valuable task only a humanoid can solve for us today?”