Manufacturers are feeling the pinch of the welder shortage. According to the EURES Report on Labor Shortages and Surpluses of 2023, around 13 EU countries are struggling to find professional welders. The American Welding Society (AWS) has also reported that the welding industry will face a shortage of about 360,000 welders by 2027.

Clearly, there is a growing demand for welders that is at odds with a shrinking workforce, and this is threatening to disrupt production.

But what could be the solution? Robotic welding is probably the answer.

What is robotic welding? This article attempts to answer this question. It also looks at how cobot welders are transforming the manufacturing industry by collaborating with human workers to offer several benefits, such as making welding safer, faster, and more precise.

As an alternative, manufacturers and those providing robotic welding services are turning to robotic welding, an automated welding technique performed by a special industrial robot.

Typically, robotic welding is performed in an isolated safety zone, and the robot performs and manages the welding tasks as programmed.

Robotic welding helps manufacturers to automate processes, increase accuracy, reduce wastage, and improve safety. There are several other advantages of robotic welding, but one of its major shortcomings is that it can be too expensive, especially for small manufacturers.

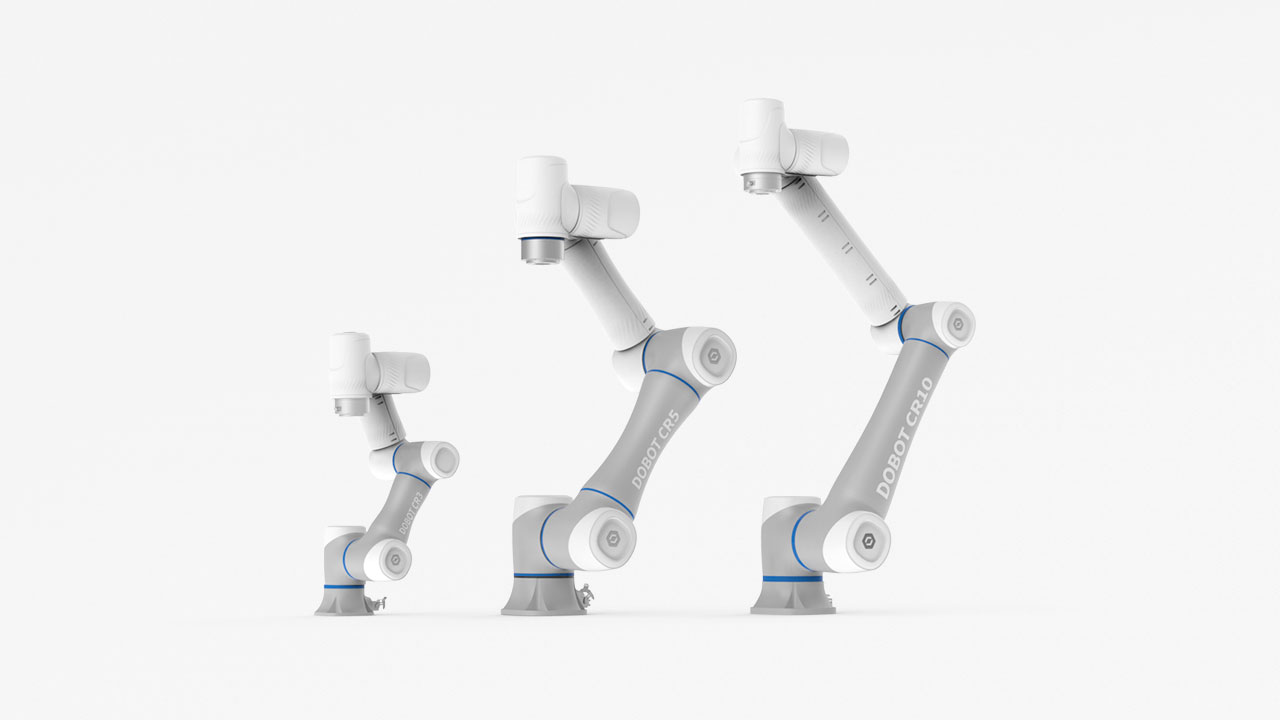

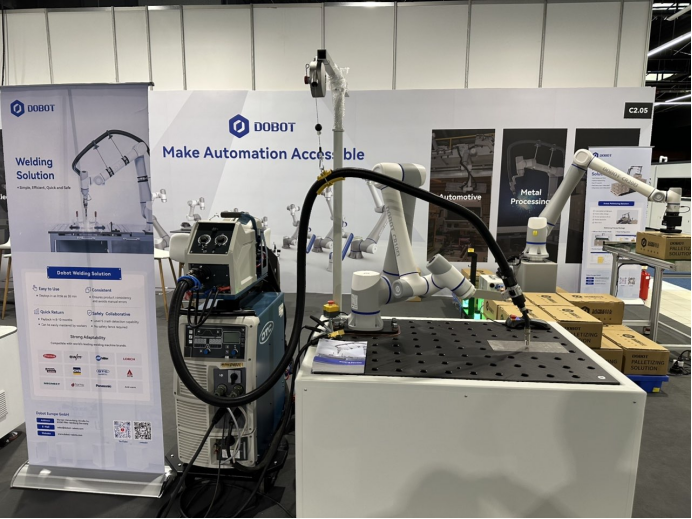

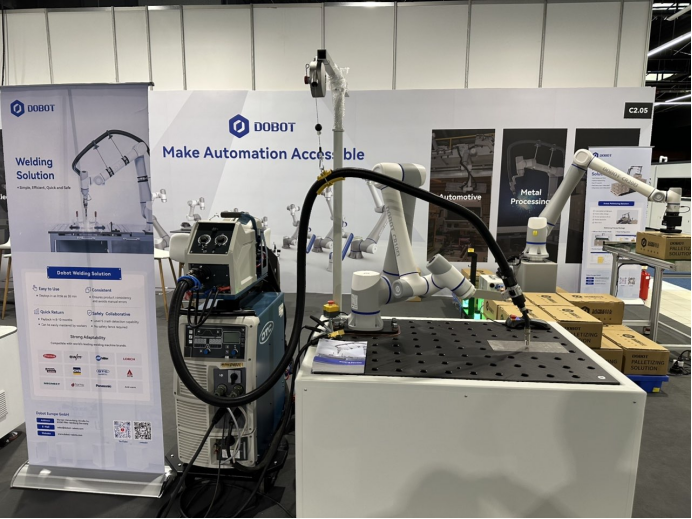

Unlike the independent traditional industrial robots used in robotic welding, cobots (collaborative robots) work alongside human welders, leveraging both strengths. These smaller, flexible, and easy-to-program robotic welding solutions make automation accessible, even for small to medium-sized companies that don’t have the budget for large-scale welding automation.

Cobot welding is gaining traction because it can solve most of the challenges faced by modern manufacturers and those who provide robotic welding services. One of its main perks is that it increases output and productivity within a small footprint. It can also improve efficiency, address workforce shortages, and help companies remain competitive.

According to this study, the collaborative robots market is expected to grow at a compound annual growth rate (CAGR) of 42.7% between 2021 and 2028. This suggests that more companies are likely to embrace cobots in the future.

Incorporating cobots into your welding workflow allows you to enjoy the advantages of robotic welding. They include:

Higher Productivity

Cobots don’t need breaks! Besides meeting the demands of heavy-duty welding, they can perform repetitive tasks consistently and for a longer time, leading to reduced downtime and higher productivity.

Ultimately, cobot welders relieve workers from mundane or repetitive tasks and allow them to focus on other assignments that require their experience and expertise.

What Is Robotic Welding? Peymar Feels Its True Power

PeyMar, a Mexican manufacturer of dental chairs, faced a challenge in production inefficiency due to traditional welding setups requiring multiple operators and machines for different workstations. To address this, DOBOT provided the company with a customized robotic welding solution using the DOBOT CR20A collaborative robot, a 7-axis sliding rail, and a Miller welding machine.

This solution enabled a single robotic arm to operate nonstop across six welding stations, requiring only one human to manage the process. The arm could weld one component while an operator replaced the completed part, ensuring minimal downtime and maximizing output.

Manufacturer of Small-Batch, Multi-Type Products Adopts Smart Welding Solution

Precise positioning and consistent weld quality, while ensuring a safe human-robot interaction, are two of the biggest challenges faced by manufacturers of small-batch, multi-type products, as they are often time-consuming and require complicated programming.

To address this pain point, one manufacturer incorporated DOBOT’s CRA cobot solution into its welding operations, eliminating the need for complex programming and allowing for easy setup of welding points. This implementation led to a consistent welding quality that resulted in a 30% increase in MIG welding productivity for the facility.

The success was attributed to the cobot’s intelligent positioning capabilities, which enabled it to automatically detect and follow the required welding seams, leading to precise and even welding across various products. In addition, the cobot’s easy-to-use programming interface allowed their human counterparts to change production specifications without needing advanced technical expertise.

Improved Product Quality

Besides increasing productivity, cobot welders produce repeatable, high-quality welds. Unlike humans, who are prone to making errors due to inexperience, fatigue, or distraction, cobot welders are known for accuracy and precision and are not susceptible to errors.

Therefore, you get repeatable, high-quality output and reduce the rework and waste costs.

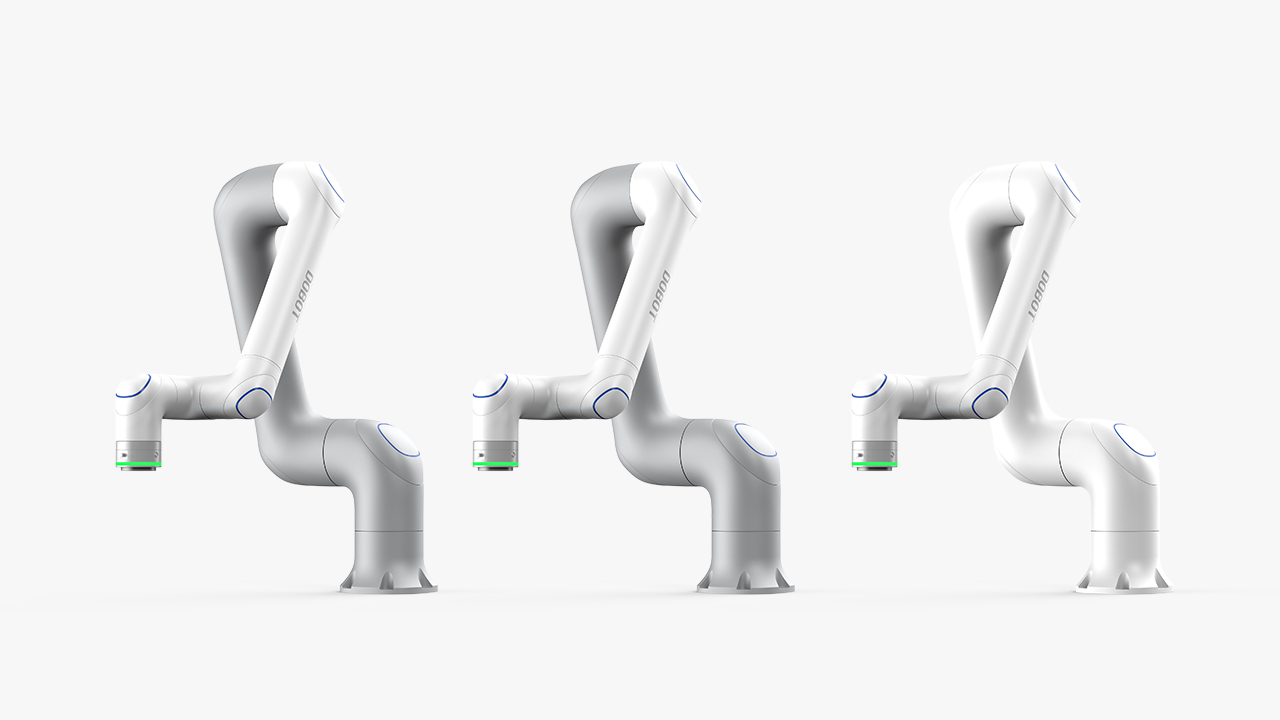

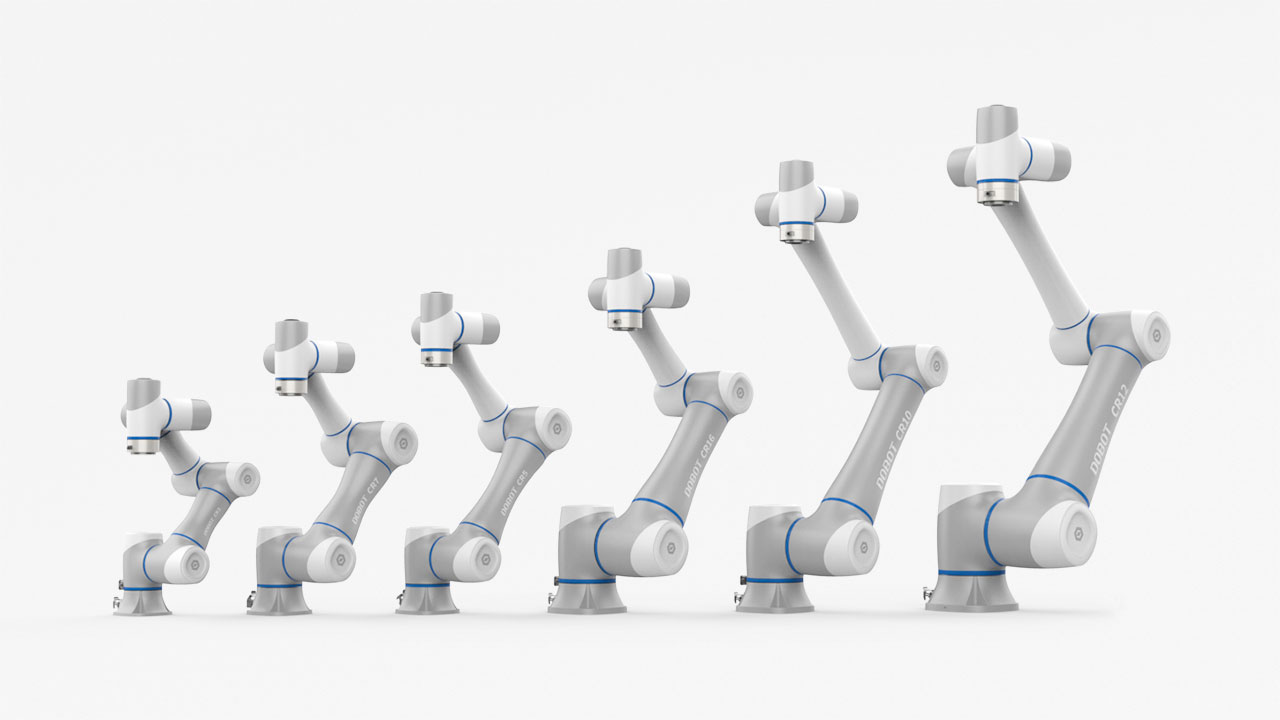

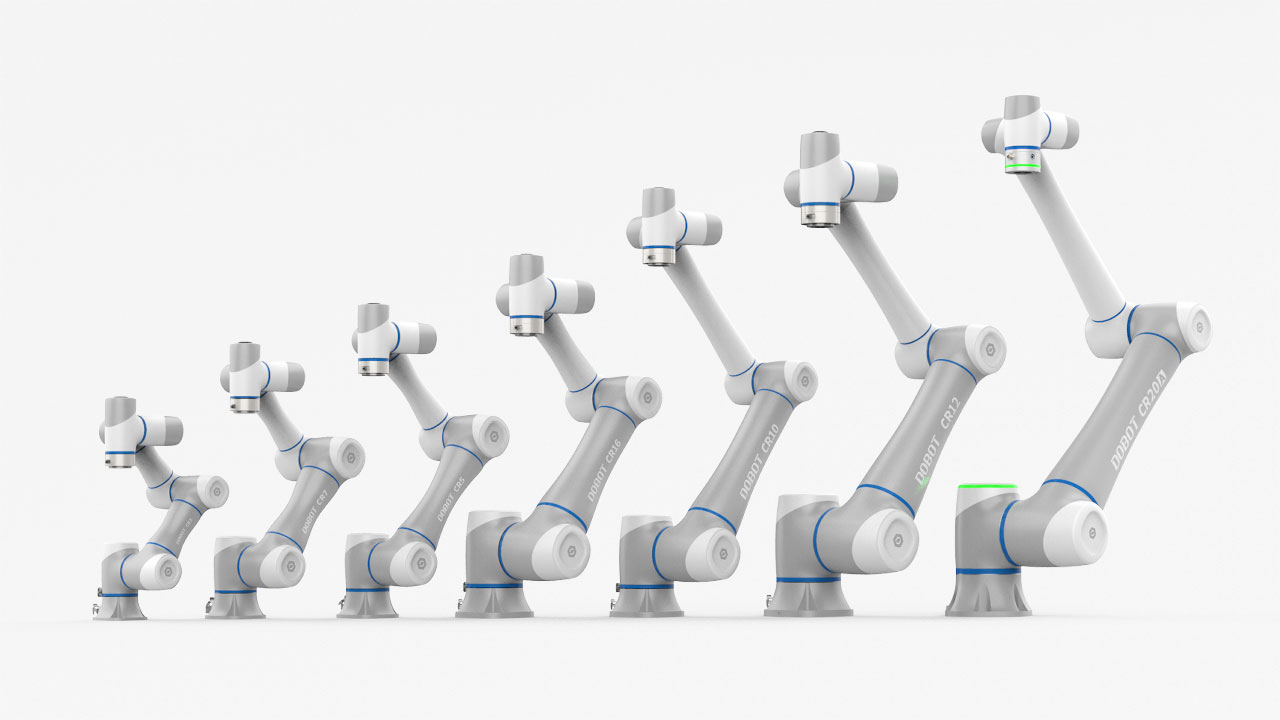

CRA Series

CRA series robotic welding solutions are calibrated with a laser calibration system, which ensures an absolute positioning accuracy of under 0.4 mm. This precision enables each robot to tackle high-precision production tasks effortlessly, thereby enhancing consistency and quality assurance in the production process.

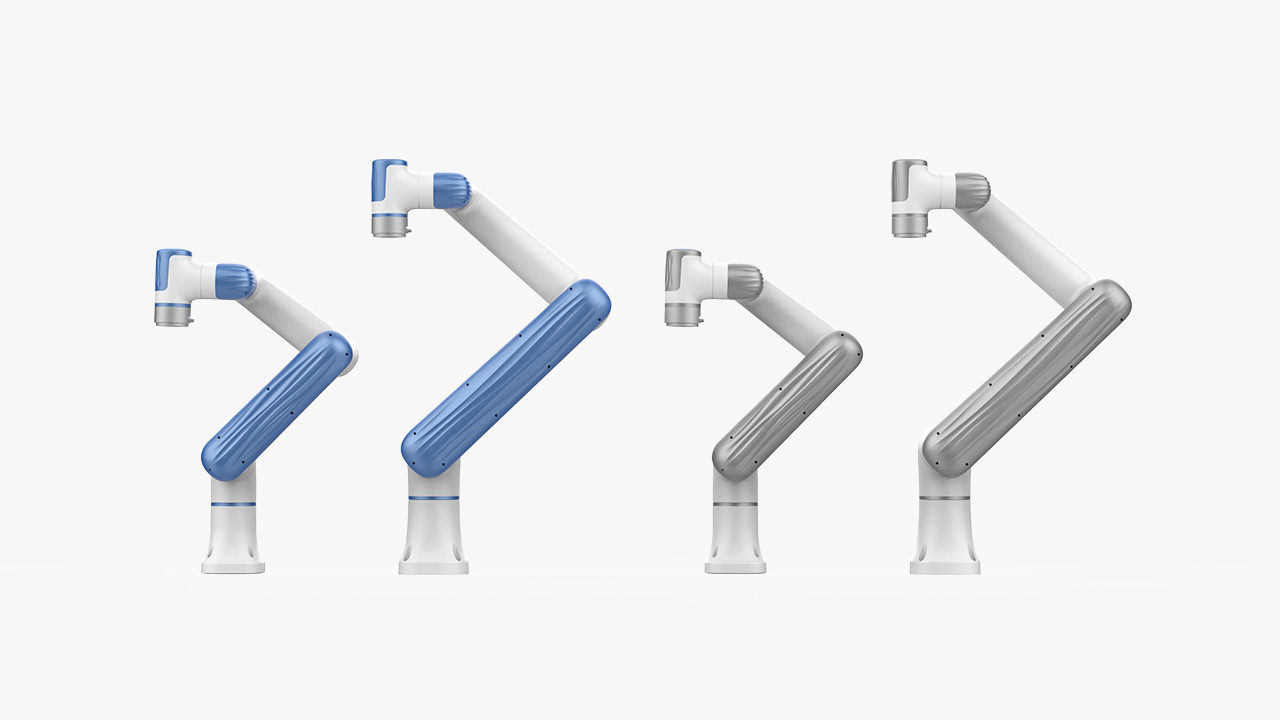

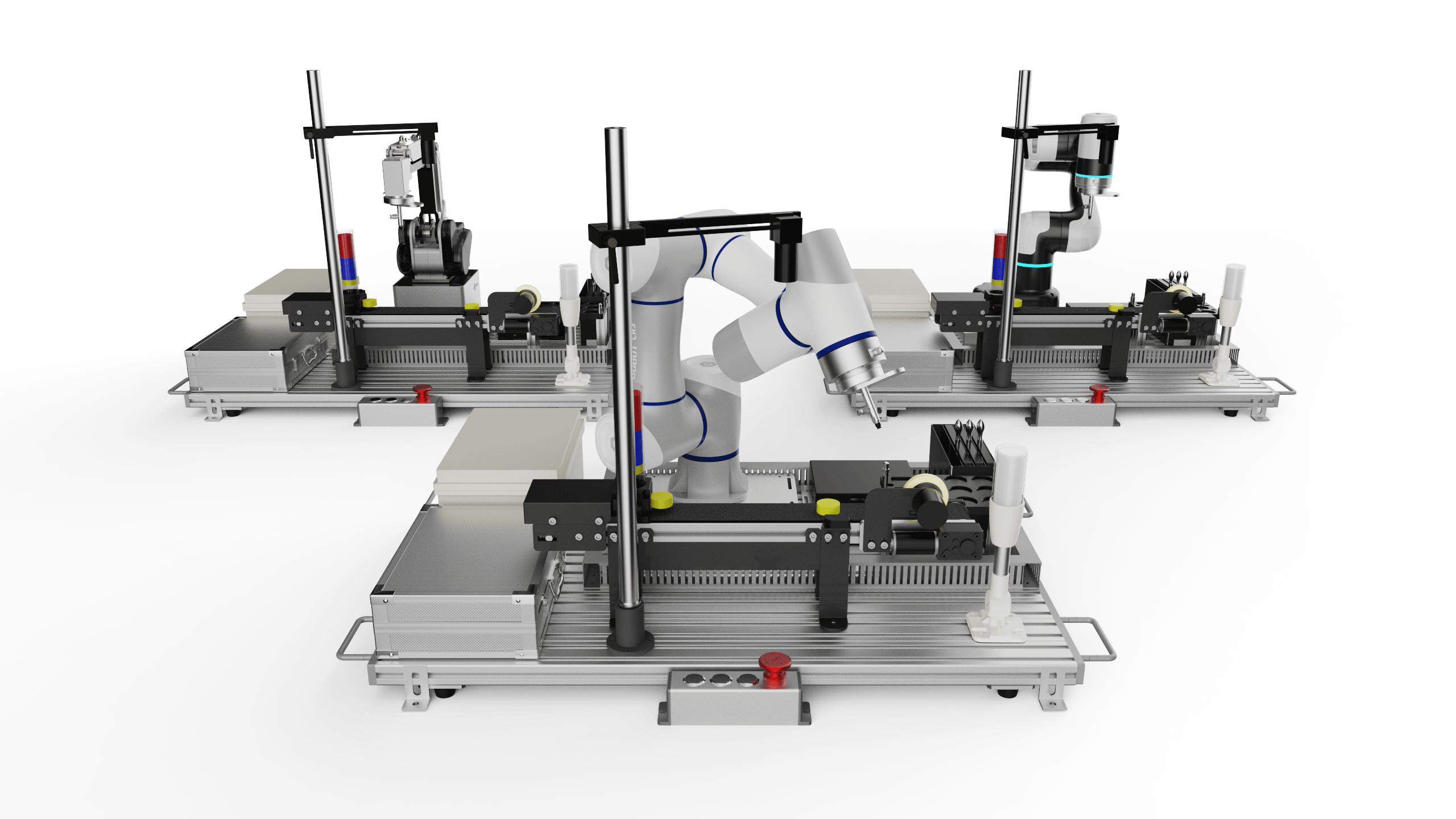

All-In-One Solution

DOBOT’s all-in-one solution is designed to streamline welding tasks and is an ideal choice for vehicle door welding. It enables autonomous spot and arc welding, utilizing laser guidance to align the welding torch accurately. Before welding, a laser scans the workpiece to determine the weld position and compensates for any deviations.

All-in-one solution

This all-in-one solution confirms the advantages of robotic welding over human welders as it can perform flawless welds repeatedly with minimal errors.

Enhanced Safety

Cobots are designed with the assumption that someone could come in contact with them at any time. Therefore, safety functions are inherently part of them, and they are meant to prevent the possibility of accidents or injuries.

Due to this increased safety, cobots can work collaboratively with humans without physical barriers.

SafeSkin

DOBOT’s SafeSkin is a contactless pre-collision safety technology that enables safer human-robot collaboration. It employs DOBOT’s proprietary pre-collision sensing technology to detect obstacles within 10-20cm and halts the robot before contact occurs to prevent potential hazards.

Dobot Safeskin with CRA Cobot Applied in Loading and Unloading for Metal processing:

While conventional cobots need to reduce speeds to around 0.25m/s in shared workspaces, SafeSkin allows collaborative operations at speeds of up to 1m/s. This optimization increases efficiency by up to four times while maintaining worker safety.

Besides the human body, the technology is also sensitive to other conductive materials like water and metals, and has adjustable sensitivity to accommodate different tasks and environments.

Safety Controller and Electromagnetic Brakes

DOBOT robots use a stand-alone safety controller that is PLd Cat.3 rated and features over 20 integrated safety functions. The CRA series, which is ISO 13849-1, ISO 10218-1, and ISO/TS 15066 certified, features electromagnetic brakes that can be engaged within 18 milliseconds to limit end-effector movement to just 0.95mm. The breaker is meant for emergencies like power blackouts and is supposed to safeguard against equipment or product damage.

The electromagnetic brakes also help maintain robotic positioning in case of sudden stops.

Increased Flexibility and Adaptability

Cobots don’t require advanced robotics expertise like traditional robotic welding solutions. They are quick to set up and program, and can even be handled by new workers.

In addition, they do not require big safety cages, and you can install them almost anywhere. These machines also tend to be versatile and can be reprogrammed to perform different tasks, depending on the production needs. This flexibility means manufacturers or those providing robotic welding services can quickly adapt to changing production needs without additional costs or downtime.

Adaptability to changing production needs is critical in industries where production lines change frequently or customization happens often.

The All-in-one welding solution, for example, comes equipped with welding software developed by Dobot Robotics to help you quickly integrate the required laser welding or arc welding applications. This software is compatible with several mainstream welding machines, supporting arc swinging modes such as sinusoidal, spiral, trapezoidal, triangular, and more, making your automated production line more robust.

The CRA series features an intelligent interaction panel that simplifies operations, such as job teaching, enabling, and effector control, providing a more flexible and convenient way of operation. These robotic welding solutions also offer more efficient debugging capabilities, allowing for a quicker setup and troubleshooting to prevent downtime.

The series comes with 24 I/O ports and PNP/NPN switching, meaning expansion can be done more quickly. In addition, they are configured with over 30 functions for cobot control and status feedback, allowing for seamless integration and control. They connect with PLC and other automation systems seamlessly. Thanks to standard communication methods like TCP/RTU, EtherNet/IP, Modbus, and PROFINET.

The CRA series is powered by user-friendly operating software that supports graphical programming, scripting, and drag-to-teach for trajectory replay. The software can work on several devices, including a personal computer, tablet, smartphone, teaching pendant, and more.

Reduced Cost of Production

Automating tasks with cobot welders increases production speed, reduces cycle times, and optimizes resource utilization. Their high accuracy results in fewer errors, ensuring efficient use of materials and minimizing the need to discard improperly welded or weak parts.

Ultimately, this translates to reduced rework and repair costs as manufacturers can automate repetitive tasks and save on labor costs without sacrificing quality. Since these robots can work around the clock, manufacturers and those who provide robotic welding services can increase production without extra labor costs. They allow humans to focus on more complex assignments, which increases the hourly production rate with the same or lower labor costs.

Compared to traditional welding robots, cobot welders cost less as you won’t need to rebuild your workshop or buy safety fences. They also consume less power compared to traditional robotic welding solutions.

All these translate to a quicker return on investment and make cobot welders a worthwhile investment in the long term.

What is robotic welding? That’s the first question you need to answer before understanding what cobot welders can do and how they can transform the manufacturing sector.

Cobot welders provide a clear path to improved efficiency, higher productivity, and higher profitability. Besides reducing errors, increasing flexibility, and minimizing rework, adopting robotic welding will dramatically mitigate safety hazards and protect your team.

When humans and cobot welders come together, they leverage their respective strengths. Robotic welding solutions provide efficiency and precision, while humans offer problem-solving and decision-making.

This kind of teamwork is the future, especially as companies get smarter with Industry 4.0 and continue seeking welding automation technologies. This collaboration will continue to provide endless possibilities for improving productivity and operational efficiency.