1、Optimal structure: Design that balances stability, passability and ease of use

- Suspension system with enhanced stability: The suspension system is customized for AMR to effectively reduce the level of vibration caused by the operation of upper module, reducing slipping caused by positive pressure changes, and increasing the support strength of the body by 20% compared with the same level.

- Efficient parts maintenance: Compared with the traditional maintenance method by opening from the top, this machine adopts a four-sided opening design, which means maintenance can be done from any side . This solves the problem of having to dissemble the entire machine from the top if there is any problem. This design reduces maintenance time by over 60%.

- Optimal balance between passability and stability: Compared with the base of the same width, the center of gravity of the machine is reduced by 5 %, allowing more stable operations compared with the base of the same stability (same level of shakiness), the structural design of the machine is more compact and the size of the whole vehicle is reduced by 8 %, passing through a narrow passage of 835 mm, this can be designed upon requirement.

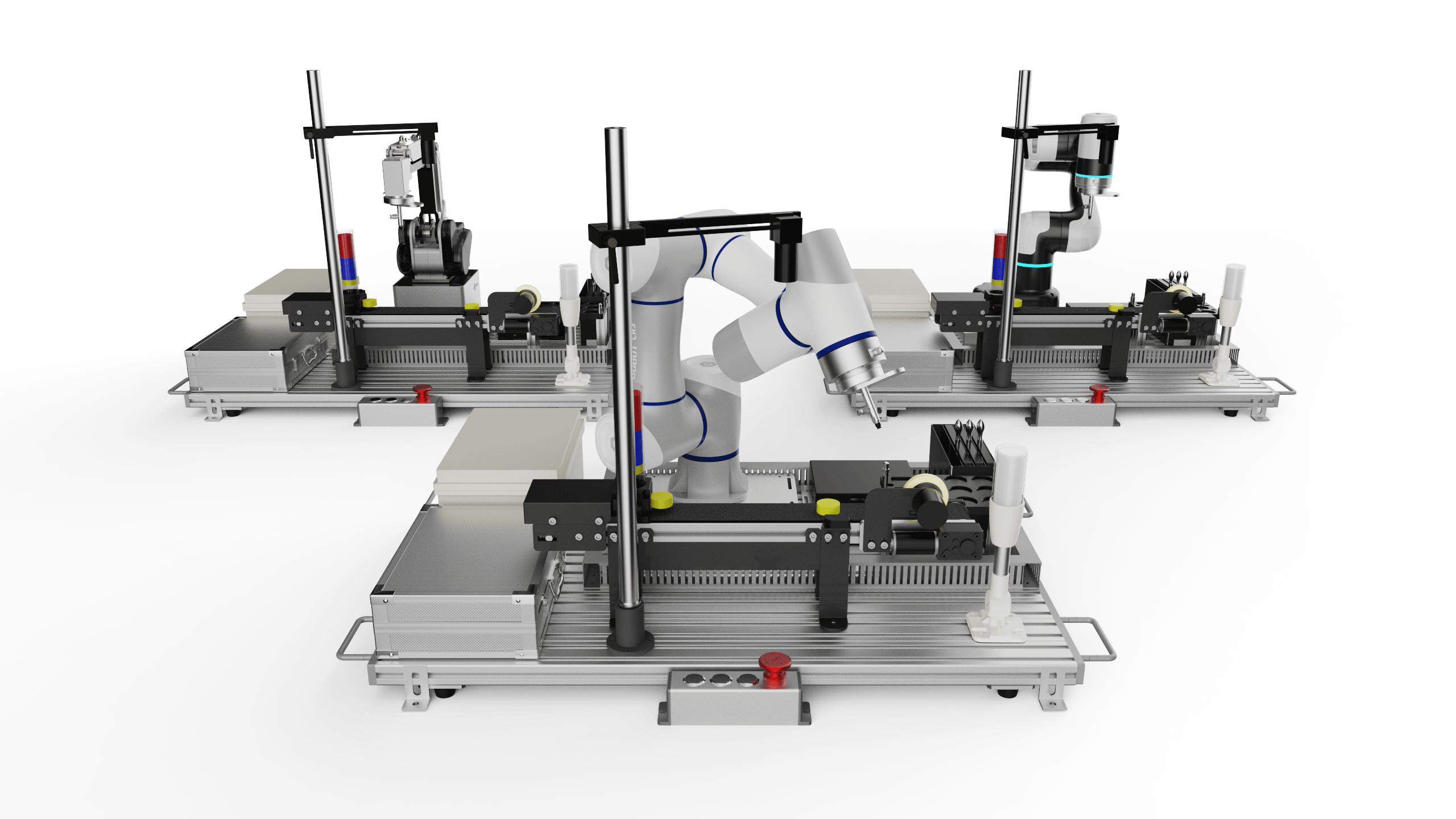

2、Adaptive ports: A rich adaptive ports reduces integration development cost.

- Wider expansion interfaces: Equipped with the most complete functional electrical interfaces, including more than 20 interfaces and status input/output to speed up further development.

- Preset safety extension: With safety radar and emergency stop switch preset, robotic arm can be interlocked and position limitation can also be carried out to ensure efficient integration.

3、Quick deployment: Multi-machine with consensus algorithm to optimize deploy efficiency.

- Using robust control and differential methods to develop a consistency algorithm for multi-machine algorithm - YOUI Unify, so different individual machines in the multi-machine system operate the same way by only using one control in the same scene. Making it unnecessary for repeated debugging for all machines under the network which shortens the assembly time.

4、Efficient integration: Professional team with rich experience to ensure delivery.

- Structured documentation: Common problems and materials of multiple transformation projects have been sorted out. The technical documentation library provides solutions for multiple industries, technical documentation, product user manuals, Q&A, video tutorials and others, which solves problems encountered in the secondary development process.

- Professional customer service: Team members experienced in automation transformation projects in industries like semiconductor, customer consumable and manufacturing, providing 24/7 service to answer problems encountered when using P200 for integration anytime.