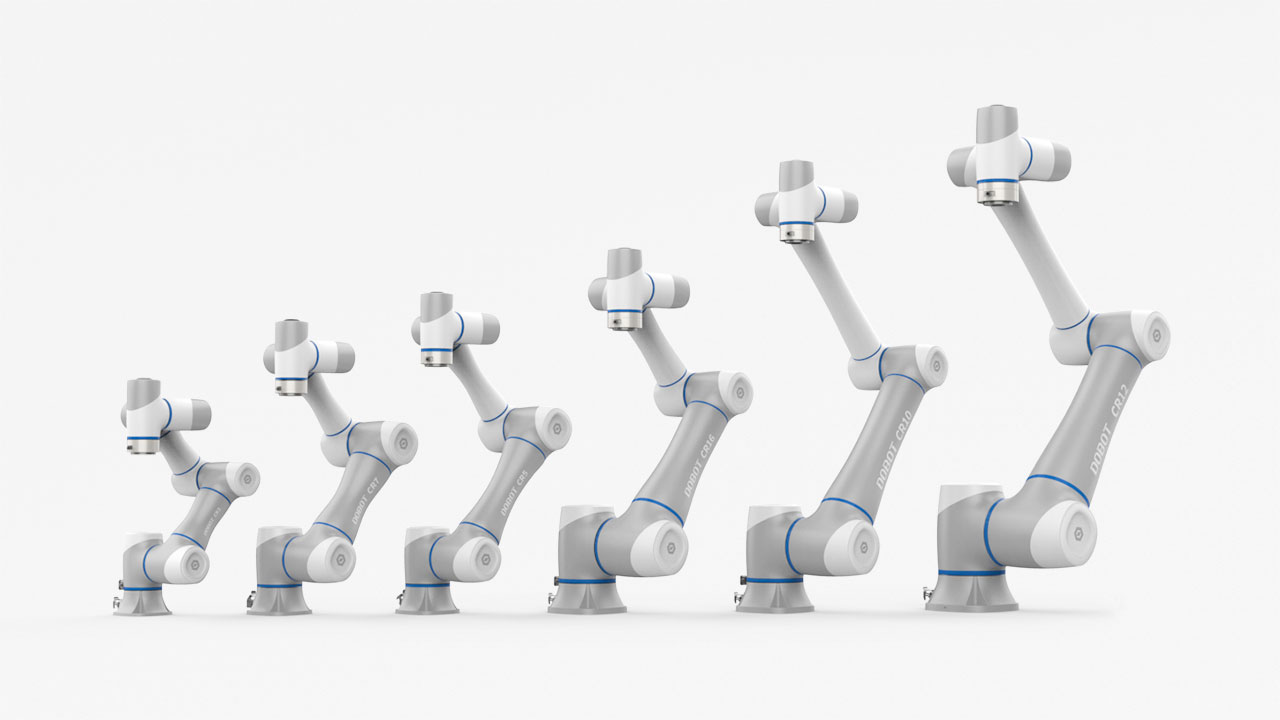

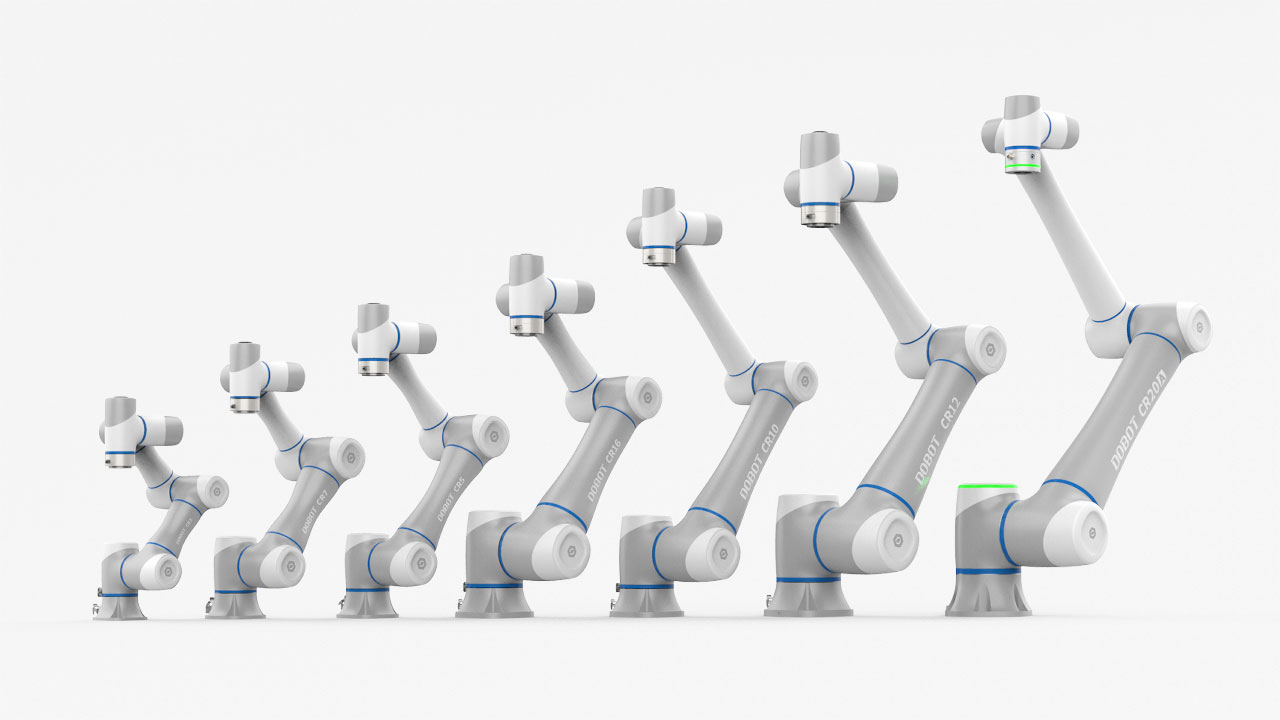

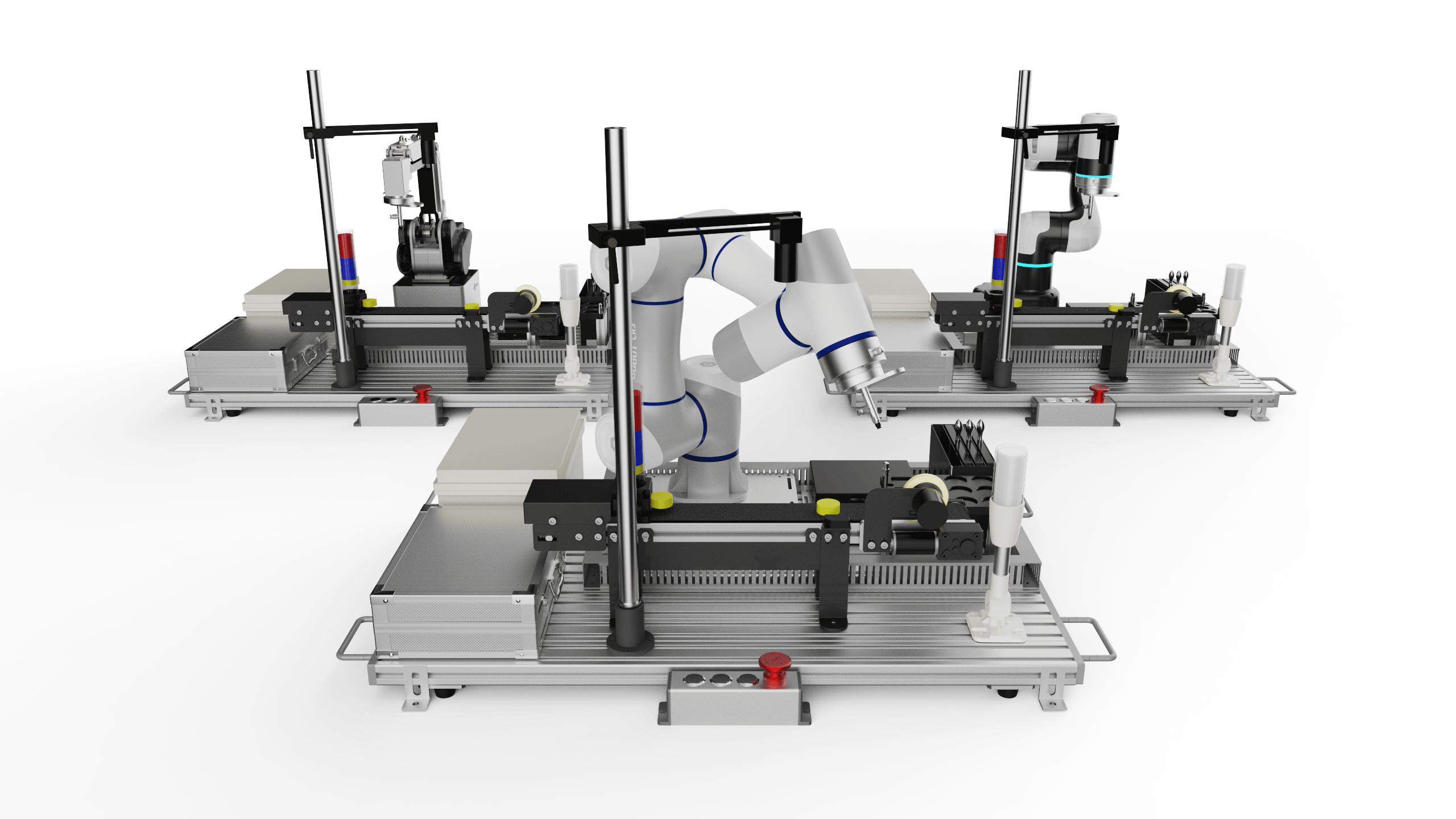

Improve Production Efficiency with Multi-Functional Robots

AMMRs are capable of mobility, manipulating, and transporting tasks, and are more flexible than traditional automated transportation equipments in reacting to changes to production lines. Each AMMR can perform tasks for multiple production lines, making it extremely useful.

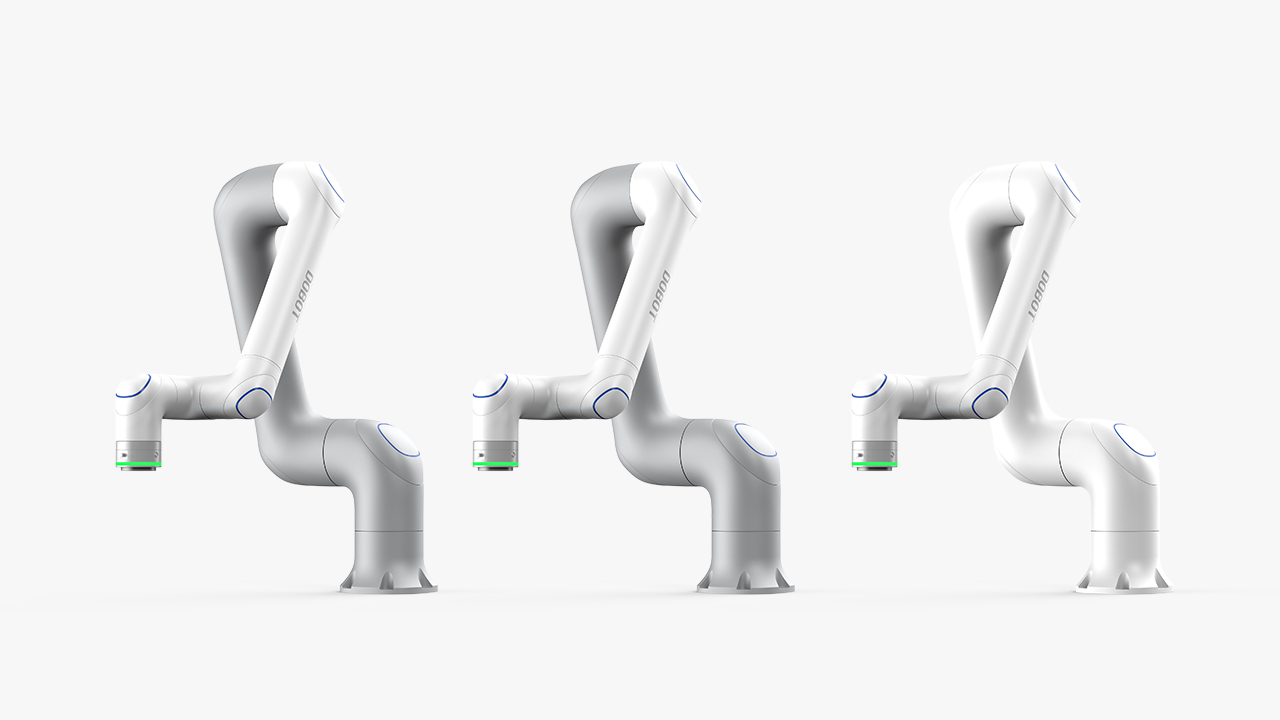

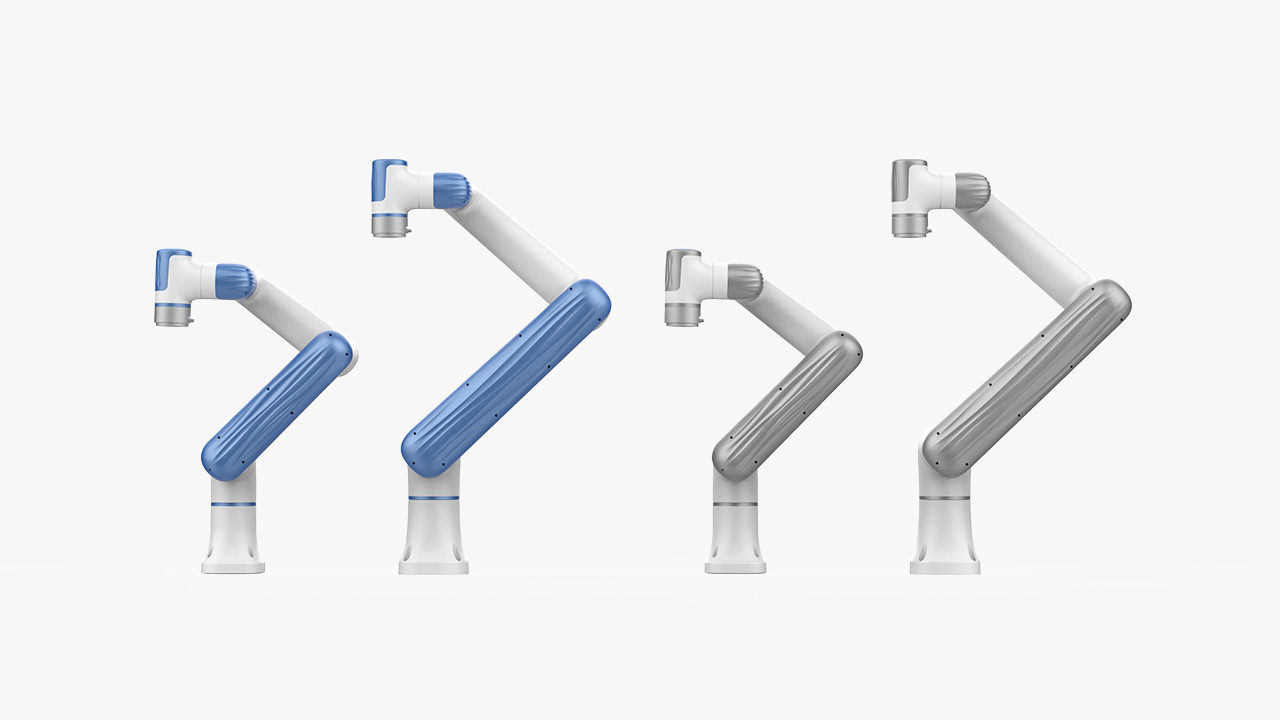

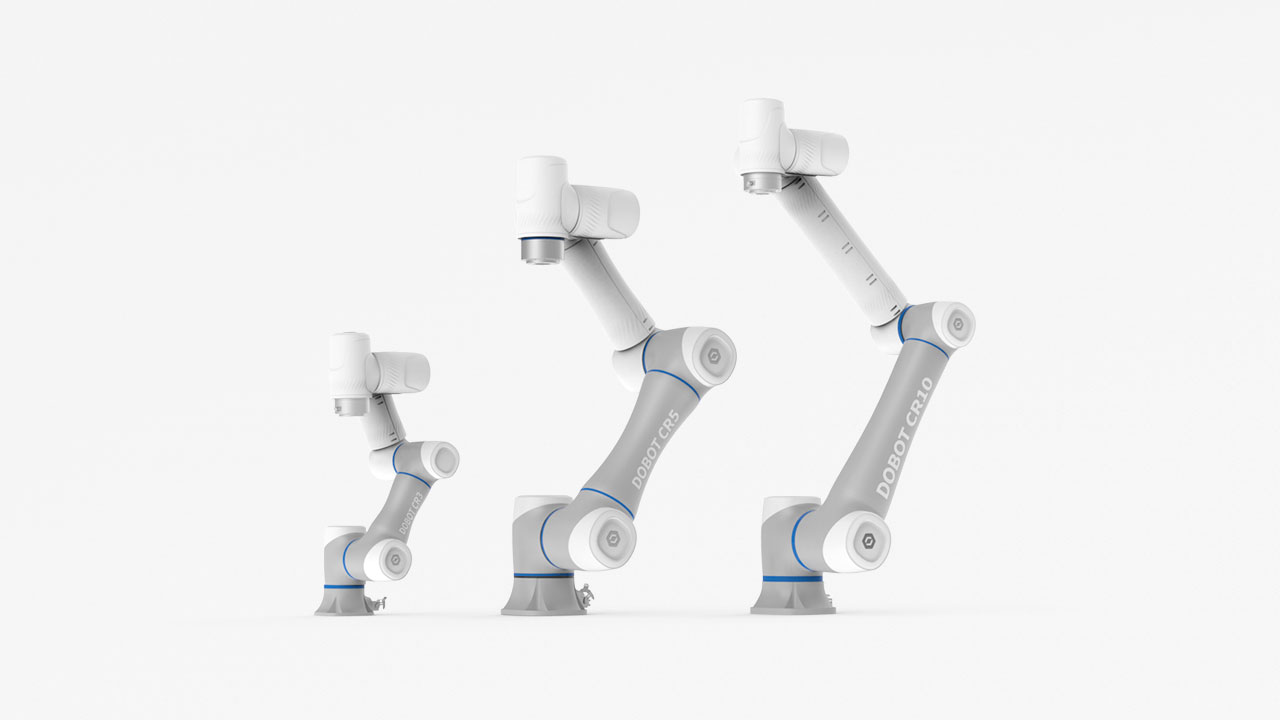

Open Ecosystem of Plug-and-Play Modules

To realize desired transportation tasks, simply attach the corresponding grippers to AMMRs. By using a all-in-one visual interface, users can easily build out tasks for AMMRs to perform. This can be done without the involvement of engineers, saving time and resources.

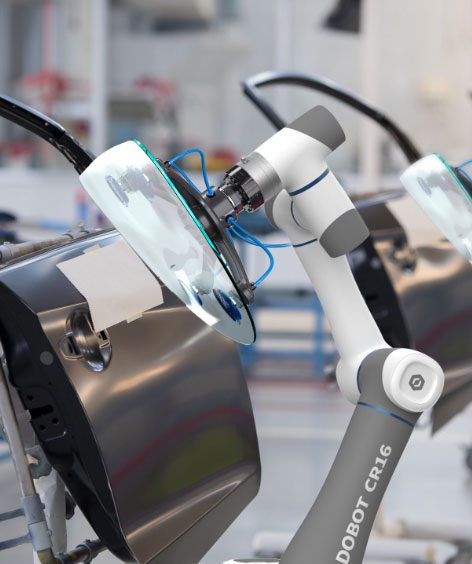

Packed with Safety Features. Certified for Dust Free Manufacturing

Dobot's AMMRs come with system level safety feasures, such as speed monitoring and safety limit switches. Having secured the CE marking, SIL2 and ISO Class 5 certifications, our AMMRs ensure the safety of humans, machines and materials, and meet the cleanliness requirements of wafer factories.