DOBOT collaborative robots integrated with RiACT’s universal operating system

unlock 24/7 production at LHM.

Denmark - July 3, 2025 - In today’s fast-paced manufacturing landscape, increasing production capacity without overburdening teams has become critical. For companies like LHM, a global supplier in the metal industry, this challenge was met with a powerful combination of smart robotics and software innovation. Through a three-way partnership between DOBOT, RiACT, and LHM, lights-out CNC machining has gone from vision to reality.

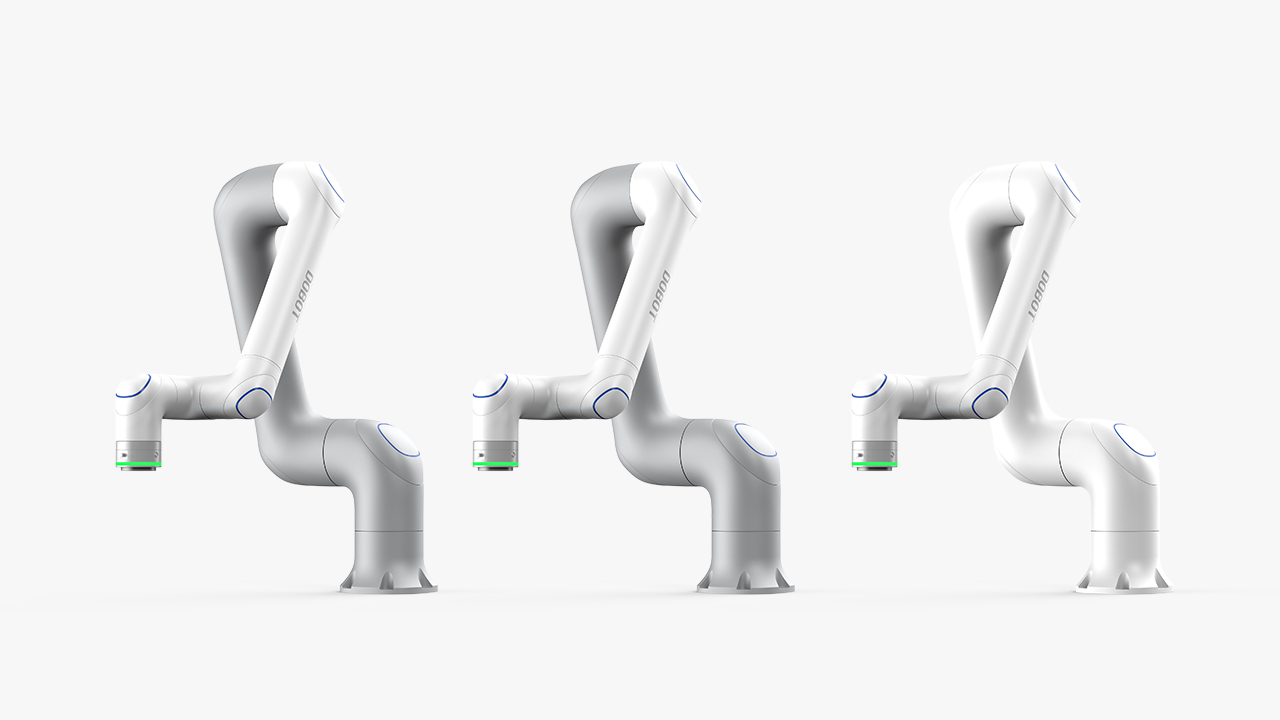

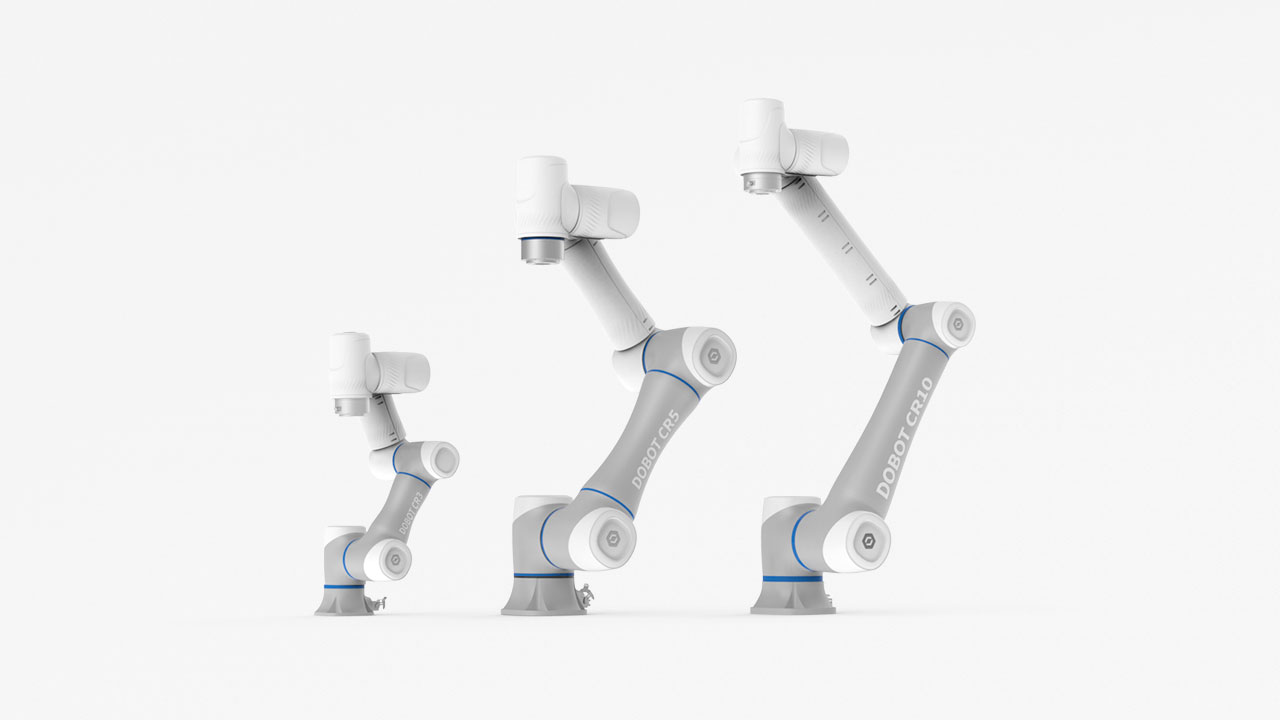

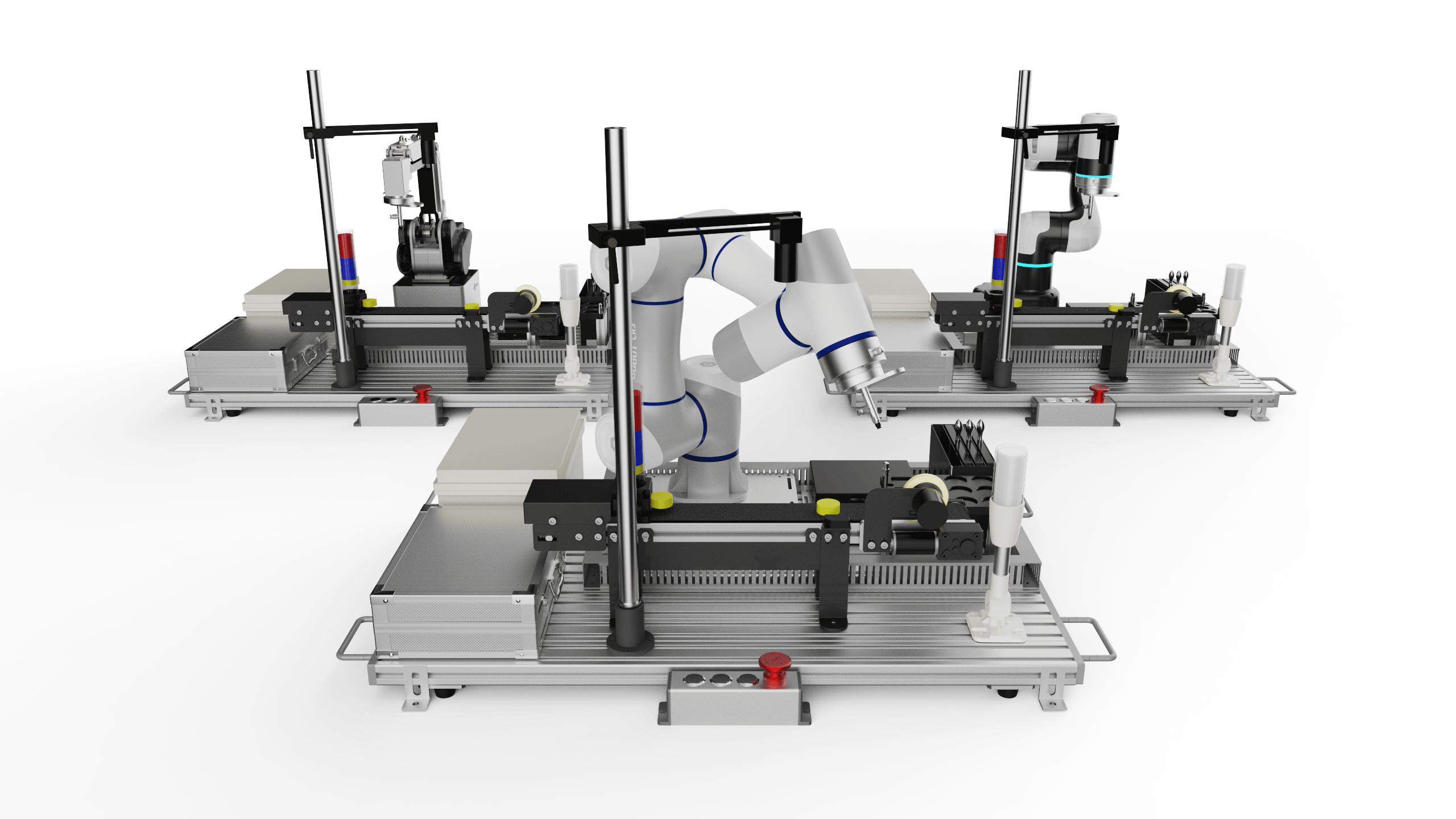

DOBOT, a leading collaborative robot manufacturer, partnered with Danish software innovator RiACT to deliver an automation solution tailored to LHM’s high-mix, precision CNC production. The result? A fully integrated system that is easy to deploy, scale, and use—helping LHM increase output, extend machine uptime, and maximize team efficiency.

“DOBOT is a very flexible robot with great support. When combined with RiACT’s software that simplifies robot control and configuration, it becomes a powerful production tool,” said Magnus Ritzau, CCO of RiACT Robotics. “You can increase your CNC machine utilization by running nights and weekends - something that’s now possible at LHM thanks to this integration.”

LHM’s goal was ambitious: enable 24/7 “lights-out” production. But with workforce constraints and rising order volumes, traditional methods couldn’t keep up. The game-changer came with the deployment of DOBOT collaborative robots powered by RiACT’s intuitive operating system.

“The challenge we face is capacity,” said Thomas Jakobse, Production Manager at LHM. “We needed to automate to handle more orders without compromising quality. DOBOT delivered a collaborative robot that matched our need for precision and adaptability, and RiACT’s software made it incredibly easy to integrate.”

At the core of this partnership is the belief that automation should empower teams, not replace them. DOBOT robots are engineered to be intelligent yet easy to operate. With RiACT’s software platform, even those without robotics experience can configure and manage robot tasks effortlessly.

“If you can use a smartphone, you can use a robot,” added Ritzau.

“The integration process with DOBOT is seamless,” said Francesco Rovida, CTO at RiACT.

“Their API makes technical deployment fast and scalable. It’s a great match.”

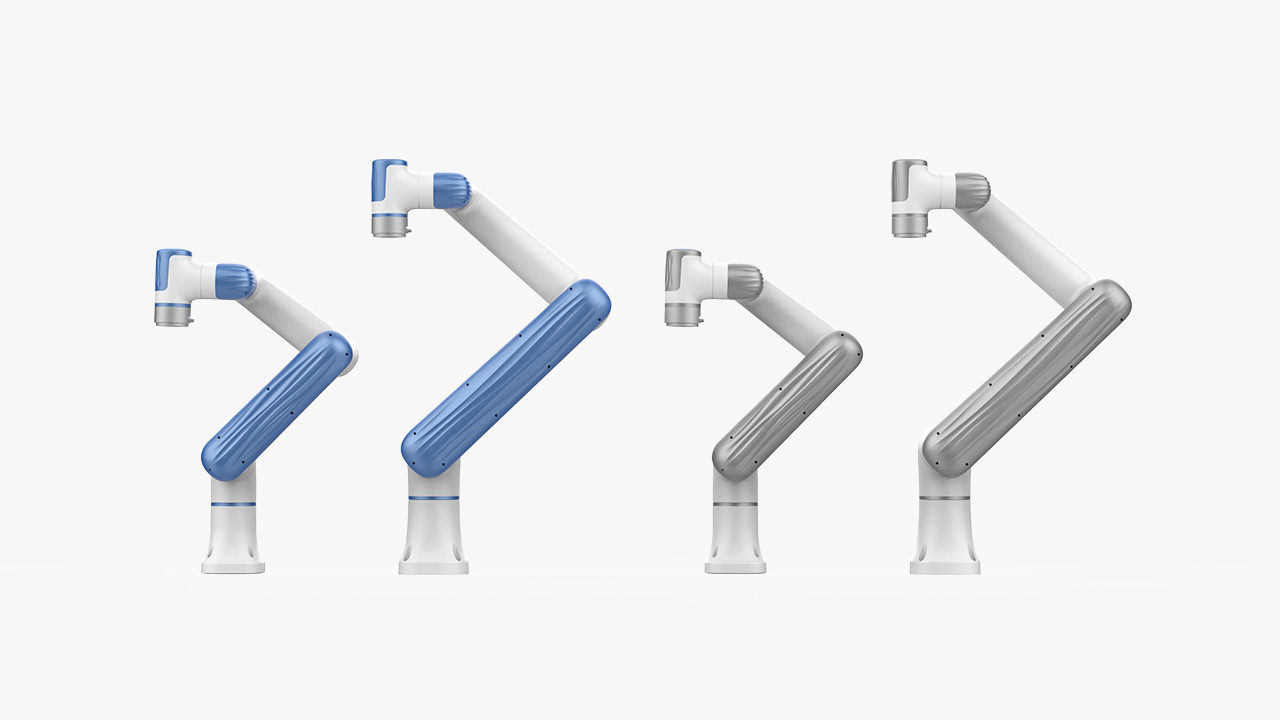

At the heart of this partnership is a shared vision: to make automation accessible and easy for all manufacturers. DOBOT cobots are built with simplicity, precision, and flexibility in mind—ready to integrate seamlessly with software ecosystems like RiACT’s. Whether deployed in small workshops or large-scale factories, DOBOT’s open and adaptable architecture allows integration with a wide range of third-party systems, making it the ideal automation partner for diverse industrial needs.

As LHM’s journey shows, automation doesn’t have to be complex or out of reach. With the right tools and the right partners, manufacturers can unlock new levels of productivity, empower their teams, and future-proof their operations.

DOBOT is not just building robots—we’re building a smarter, more accessible future for manufacturing.

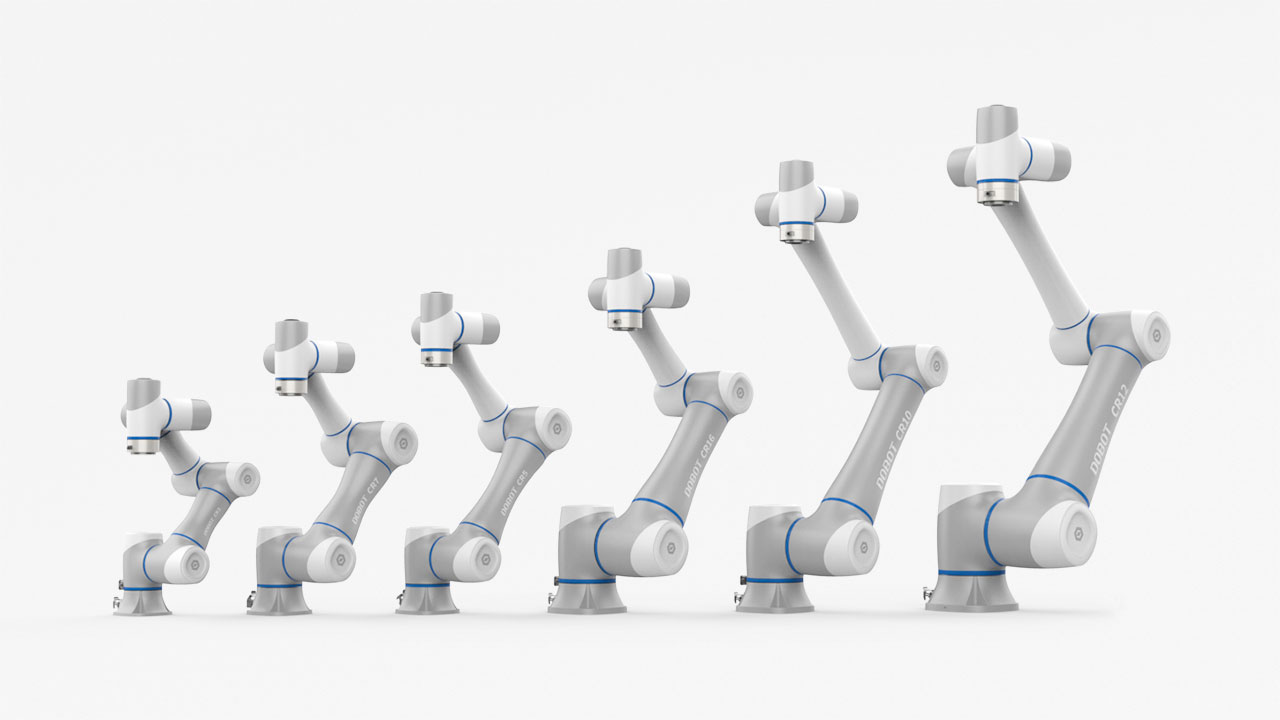

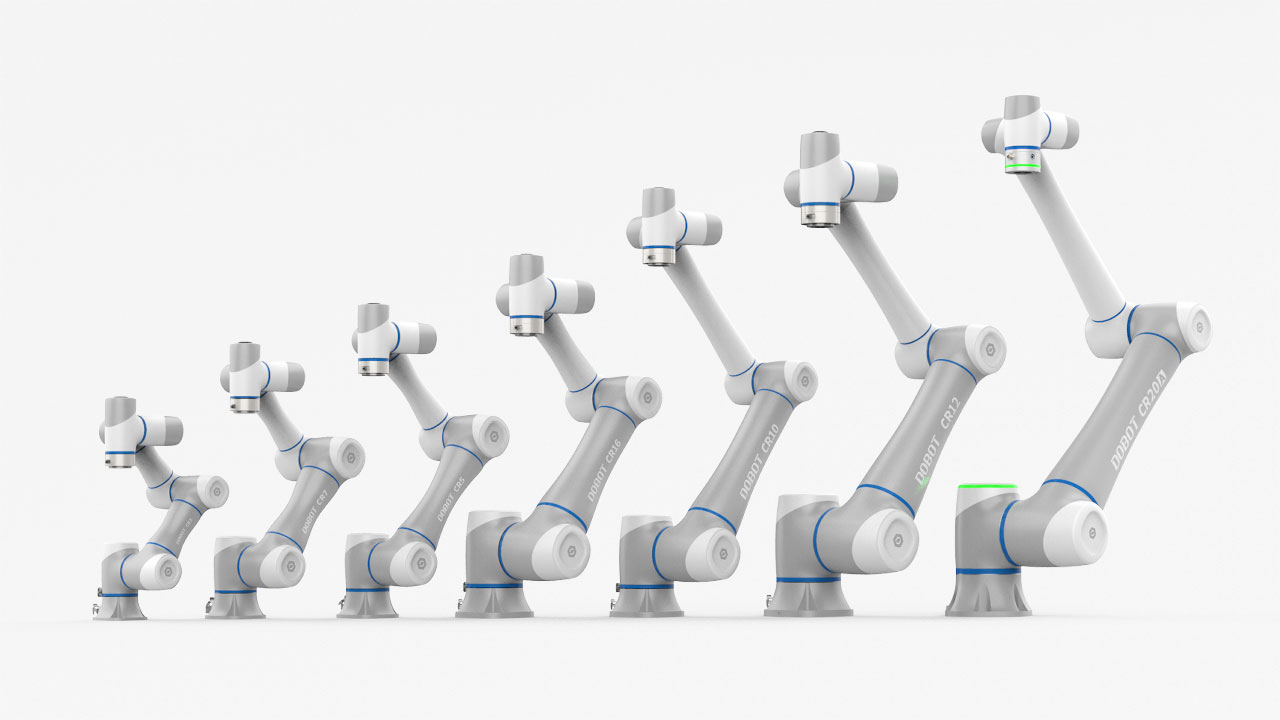

Founded in 2015, DOBOT is one of the global leading providers of collaborative robots and the creator of desktop-grade robotic arms. Our core technologies are developed in-house, including AI, system integration, intelligent sensing and more.

DOBOT cobots and solutions are widely used in the manufacturing, healthcare, service and retail sectors, enabling automation, intelligent transformation and flexible production for clients to achieve maximum output with minimal labor. DOBOT collaborates closely with academics through the integration between industry and education, raising the next generation of talents to advance the industry forward.

DOBOT, ranked No.1 Collaborative Robot exporter in China, possesses a sound global network by establishing branches in the United States, Japan, Germany, Thailand, and other countries. Over 80,000 Dobot cobots have been delivered and deployed worldwide. Today, DOBOT's cobots and solutions can be found in automation in over 100 countries and regions.

Marketing Contact

marketing@dobot-robots.com