DOBOT Robotics, as the only embodied intelligence enterprise that has "emerged from real-world manufacturing sites" and the earliest to achieve globalized education deployment in this field, is now redefining the integrated development of industry and education amid the wave of embodied intelligence. Against the backdrop of the 2025 World Robot Conference's theme "Smarter Robots, More Intelligent Embodiment," the company leverages its robust industrial foundation and global educational perspective to drive this transformation.

On August 8, 2025, the World Robot Conference (WRC) grandly commenced in Beijing. Held concurrently with the conference, the World Robot Contest — renowned as the "Olympics of Robotics" — has been repeatedly included in the Ministry of Education's Official Competition White List, underscoring its academic authority and global influence.

Since joining in 2017, DOBOT Robotics has consecutively hosted its exclusive DOBOT Intelligent Manufacturing Challenge for the 9th year at the World Robot Contest. In 2018, the competition attracted enthusiastic participation from Asia-Pacific countries including Japan, South Korea, and Singapore. Since then, its global influence has grown steadily, with 190 successfully held international and domestic tournaments to date, engaging over 10,000 students and faculty from 500+ institutions across 15 countries and regions. This year marks another milestone as the competition expands its global footprint, welcoming debut teams from Kazakhstan, Mexico, and Turkey.

The DOBOT Intelligent Manufacturing Challenge, hosted by the Chinese Institute of Electronics and co-organized by Shenzhen DOBOT Robotics Co., Ltd., will hold qualifying tournaments and championships in 2025 across Beijing, Sanya, Inner Mongolia, Zhejiang, and other Chinese cities. Current registrations include 500 youth teams with nearly 2,500+ participating students and mentors.

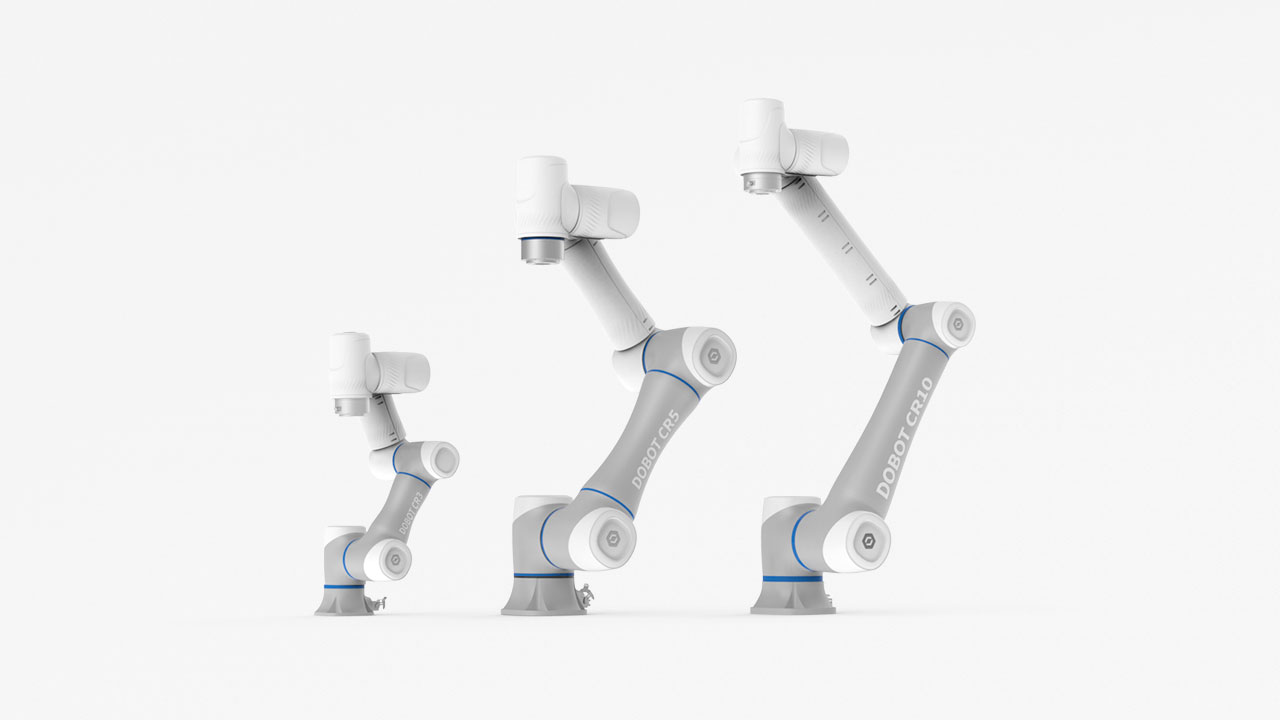

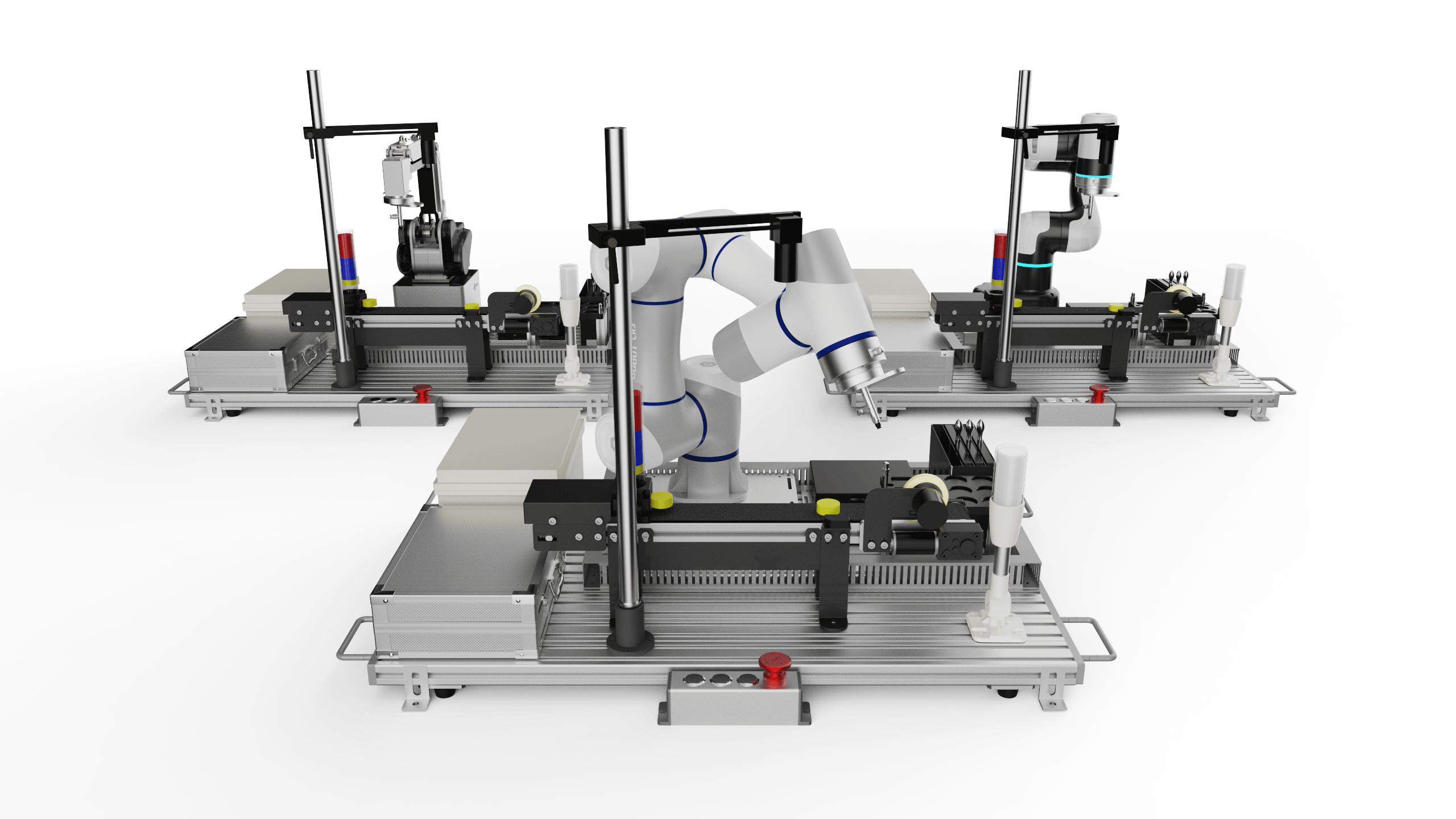

This year's competition is themed around China's Lunar Exploration Program, utilizing intelligent robotic arms as the core platform. Aligned with real-world demands for AI and robotics across industries, it integrates AI vision recognition, robotic arm control, and autonomous navigation technologies. Through practical industrial simulations — including automated production line tasks, vision-guided operations, and flexible collaborative challenges — the event empowers global youth to master industry-ready AI innovations and advance their technological capabilities.

Contestants from China, Mexico, Turkey, and Kazakhstan competing on the same stage

China's victorious moment at the awards ceremony

Ms. Stella Wang, Vice President of Marketing and Global Head of Education at DOBOT Robotics, presented awards to the winning international teams.

Empowered by the Chinese Institute of Electronics, the DOBOT Intelligent Manufacturing Challenge has solidified its position as a core independent event within the World Robot Contest ecosystem through nine years of dedicated development. Today, it stands as a globally influential official robotics competition, with select achievements now internationally recognized. As a key driver of innovative talent cultivation worldwide, the challenge has been integrated into national AI education frameworks across multiple countries.

On the scene, Walter Zamarron, Head of Digital Policy for the Chihuahua State Government in Mexico, stated in an interview with DOBOT: "In Mexico, we have collaborated with DOBOT through Academemia STEM to jointly build this competition platform. It promotes innovation and technological development among students, teachers, and professionals in Mexico and Latin America, fostering the growth of skilled talent and new technology creators. This platform has become a vital vehicle for popularizing artificial intelligence education in Mexico."

Mr. Sami, Competition Director from Turkey's 15 Temmuz Şehitlerim Teknoloji İmam Hatip Lisesi stated: "As a model school in Turkey, we recognize the DOBOT Smart Manufacturing Challenge as a transformative platform that significantly enhances students' practical skills and innovative thinking in AI, robotics, and smart manufacturing. Furthermore, at DOBOT's exhibition, we observed the humanoid robot DOBOT Atom Ⅱ with its advanced upper-limb/lower-limb coordinated control capabilities. We anticipate its diverse future applications across industrial, commercial service, and domestic scenarios."

Through its global competition platform, DOBOT has created a vital nexus connecting industry requirements with educational development, delivering end-to-end solutions that encompass curriculum design, training programs, laboratory setup, teacher accreditation, and research commercialization for primary and secondary schools, vocational colleges, and universities worldwide. The company's extensive academic network now includes partnerships with over 6,500 leading institutions across three continents from Britain's Russell Group members like the University of Bristol and University of Birmingham, to Germany's Technical University of Munich and Koblenz University of Applied Sciences, along with prestigious American universities such as Stanford and UC Berkeley - establishing DOBOT as a truly global force in STEM education innovation.

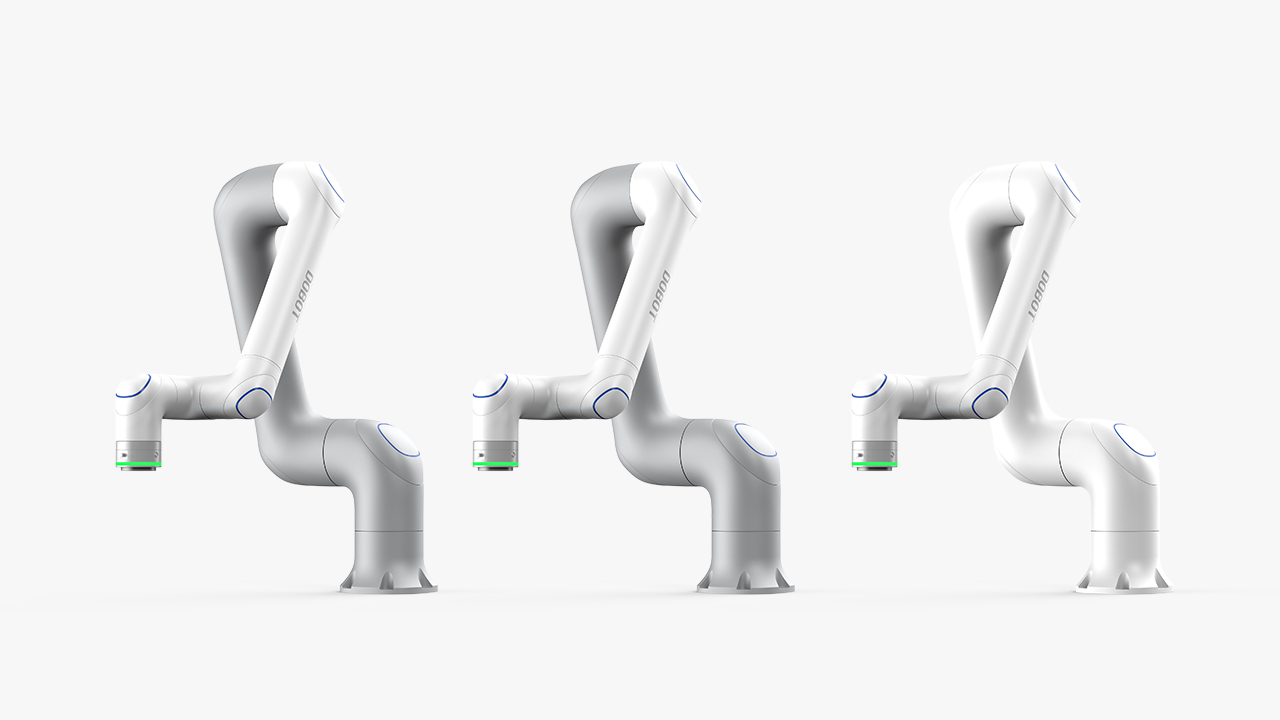

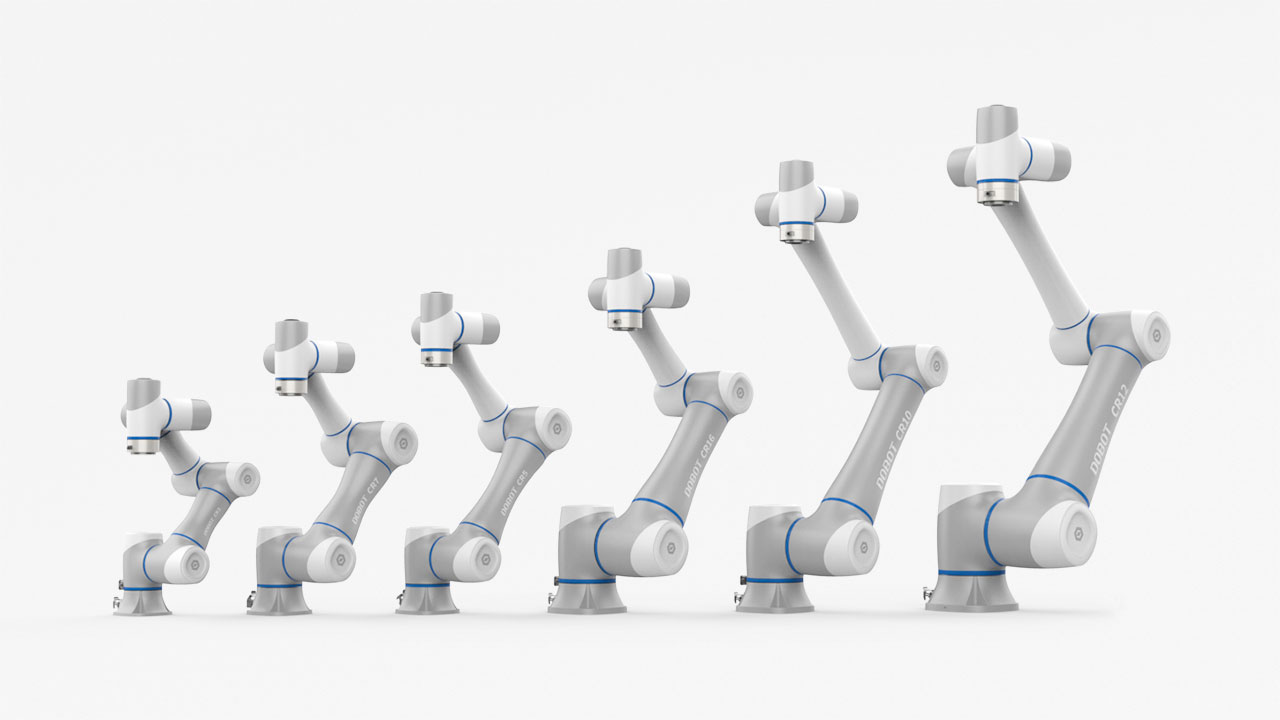

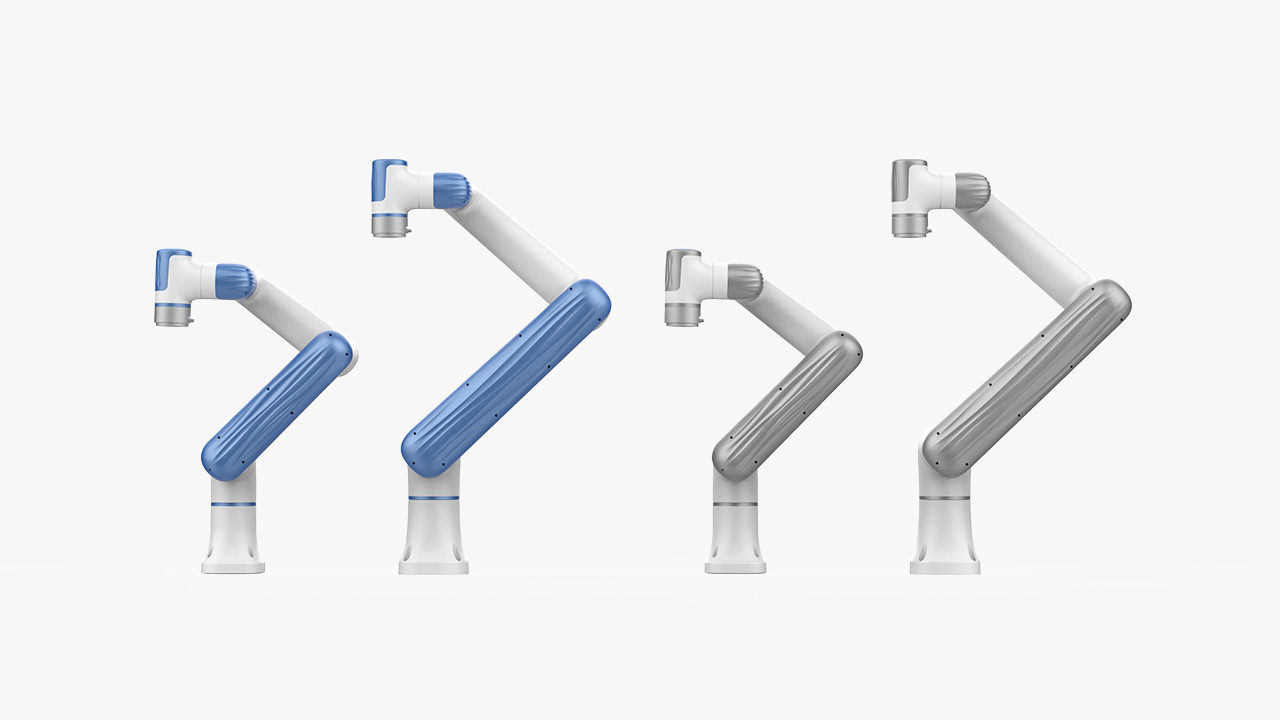

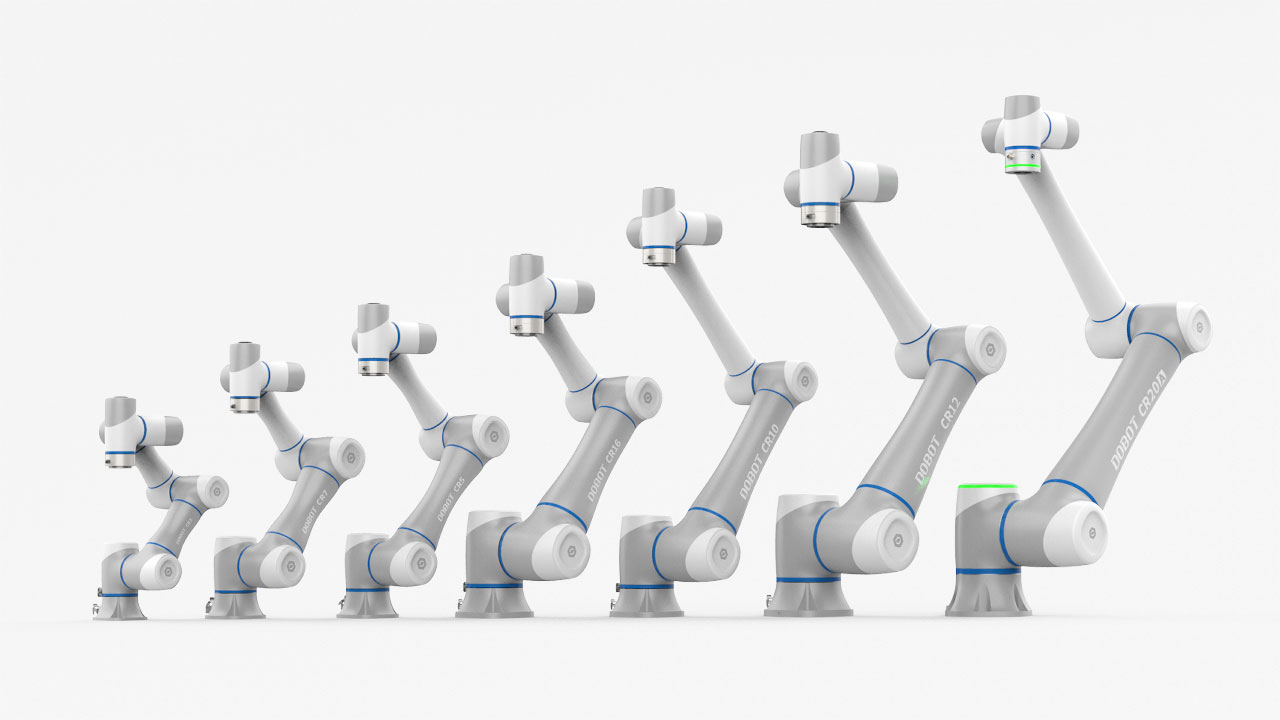

DOBOT electrified the conference with the debut of its next-generation DOBOT Atom Ⅱ embodied humanoid robot. The showcase presented a comprehensive ecosystem through a multi-form robotic matrix combining precision robotic arms, agile humanoids, and adaptive multi-legged platforms that demonstrated seamless full-scenario integration across industrial, commercial, and domestic environments. This exhibition-competition fusion vividly illustrated the company's complete academia-to-industry solution pipeline, from fundamental research to real-world implementation

DOBOT Atom Ⅱ Embodied Intelligent Humanoid Robot

As the first embodied intelligence company to achieve global education deployment and the only industry-native player rooted in real-world manufacturing, DOBOT has pioneered seamless technology transfer from competition arenas to industrial applications— DOBOT has established a globally interconnected competition ecosystem, featuring International Platforms like World Robot Contest (WRC), BRICS Skills Competition and National Excellence such as China Collegiate Intelligent Robot Contest, Vocational Skills Competition of the People's Republic of China, National Industry Vocational Skills Competition.

Meanwhile, DOBOT's embodied intelligent humanoid robots have undergone multi-scenario validation by global industry leaders, including: Top Research Institutions (eg. Tencent Robotics X Lab, Shanghai AI Laboratory, DAMO Academy), Industrial Powerhouses ( eg. MAZAK Japan, ASKA Japan, AI Korea), Global Partners ( eg. Alta Vietnam, CampuStore Italy, Aurotek Technology).

DOBOT has pioneered the launch of its Embodied Intelligence Industrial Application Development Program for universities worldwide. Leveraging its collaborative 'Cloud LLM + Edge Computing + Embodied Terminal' architecture developed with leading cloud platforms including Tencent Cloud, Alibaba Cloud and Baidu Cloud, this initiative facilitates university-industry partnerships to jointly develop embodied intelligence educational resources and establish innovation practice centers.

DOBOT has created a comprehensive ecosystem that harnesses competitive platforms as connectors, industrial expertise as its bedrock, and educational pathways as access points to tackle the transformative potential of embodied intelligence. By seamlessly linking industry, academia, and research, we are positioned to advance this field through global partnerships across all educational levels from K12 to vocational training, universities and research institutions to corporate collaborators. Our forward-looking strategy focuses on cultivating specialized talent for the embodied intelligence sector while establishing continuous professional development opportunities and pioneering innovative cross-industry collaboration frameworks that will shape the future of AI integration.