Robot Palletizers vs. Traditional Methods: Finding the Right Fit for Your Operations

Palletizing—stacking goods onto pallets for storage or shipping—is the heartbeat of logistics and manufacturing, driving efficiency and speed in warehouses across the United States. Whether you’re a small business or a large-scale operation, how you palletize can shape your bottom line. But with options like manual labor or advanced robotic palletizing systems, which method fits your needs best?

As automation reshapes industries, businesses are under pressure to boost productivity while keeping costs in check. In this article, we’ll compare traditional and robotic palletizing, exploring their costs, scalability, and real-world impact.

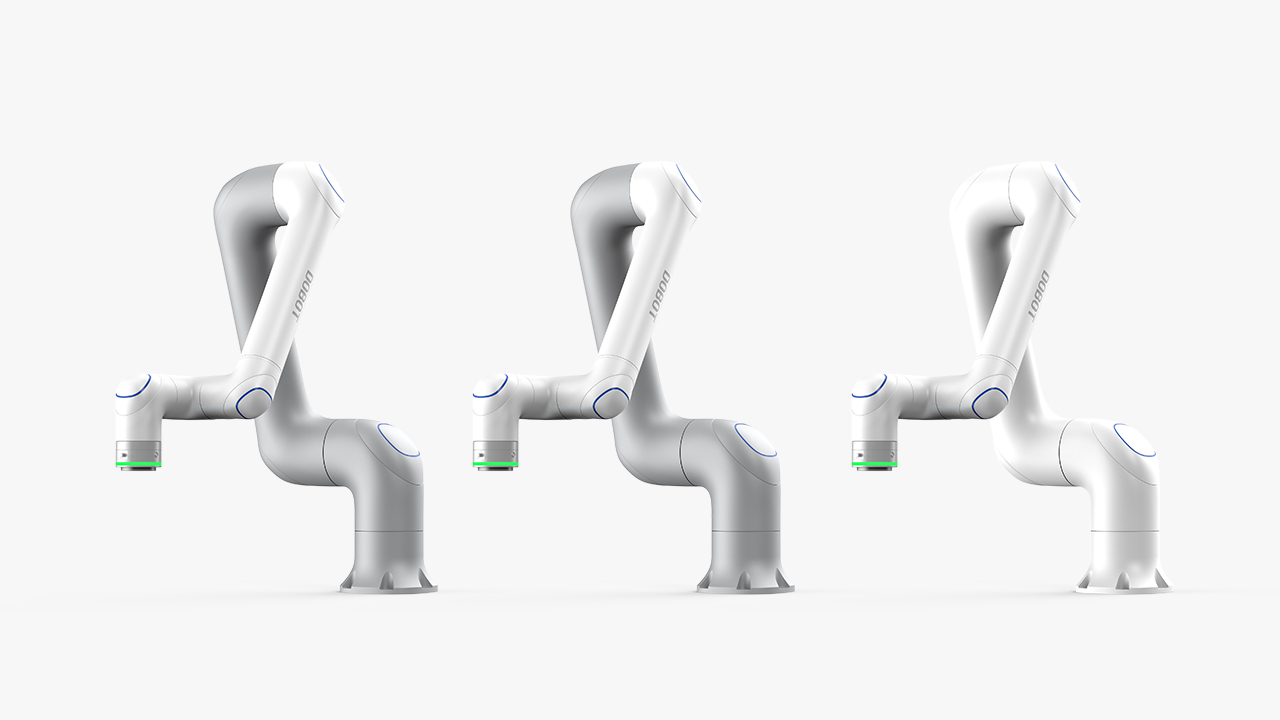

Our goal? To help you decide what’s right for your operations. Along the way, we’ll highlight DOBOT’s cutting-edge solutions, like the CRA Series, designed to make automation accessible and efficient. Let’s dive in and find the perfect fit for your future.

Traditional palletizing methods remain a staple in many warehouses and factories, relying on human effort and simple tools. While these approaches are accessible, they come with challenges that can limit efficiency in modern operations. Let’s explore how they function, their advantages and drawbacks, and a real-world example.

Manual/Semi-Automated Processes

Conventional palletizing involves workers manually stacking goods onto pallets, often using basic equipment like forklifts, pallet jacks, or simple conveyor systems. Semi-automated setups may incorporate tools for layer forming, but human labor drives the process. These methods are straightforward, requiring minimal technology, and are commonly used in smaller or less automated facilities.

Pros and Cons

Pros:

- Low Initial Investment: Manual methods require only basic tools and labor, making it a cost-effective choice for businesses with limited capital.

- Simplicity: For operations with low palletizing volumes or irregular schedules, these methods are easy to implement without advanced training or equipment.

- Quick Returns: Having such systems eliminates a good portion of the training needed to create skilled employees, which shortens onboarding periods and reduces costs.

- High ROI: With lower operational costs and greater operational efficiency, companies are likely to see better returns, in addition to quick returns.

Cons:

- Labor Dependency: Output depends on workers’ stamina and skill, leading to variability in speed and quality compared to automated systems.

- Safety Risks: Repetitive lifting and heavy loads increase the likelihood of injuries, such as musculoskeletal disorders, impacting worker well-being. The Bureau of Labor Statistics reports that musculoskeletal disorders account for nearly 30% of the total number of all cases involving days away from work by employees.

- Inconsistent Output: Human error can result in misaligned pallets or damaged goods, potentially requiring rework and affecting efficiency.

Case Study Example

Consider a small craft brewery with 18 employees, grappling with manual palletizing during peak demand. Manually stacking 40 crates (800 bottles) per pallet involved repetitive lifting, causing fatigue and safety concerns. Production bottlenecks and rising labor costs hindered operations.

By adopting a robotic gripper that lifts four crates at once, they eliminated bottlenecks, reduced physical strain, and reassigned workers to tasks like quality control, improving overall efficiency.

How Robotic Palletizing Systems Work

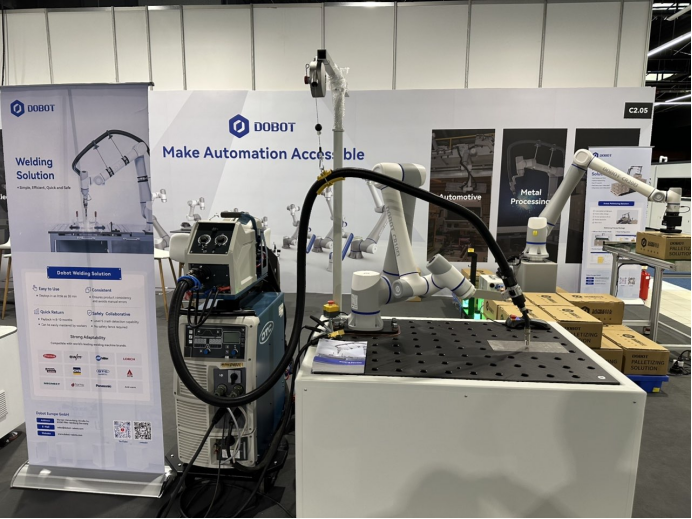

Robotic palletizing systems are transforming logistics and manufacturing by automating the stacking of goods with precision and efficiency. These advanced solutions outperform traditional methods, offering businesses scalability and reliability. Let’s explore the types of robots, their standout features, and why DOBOT’s systems are a game-changer for operations across the world.

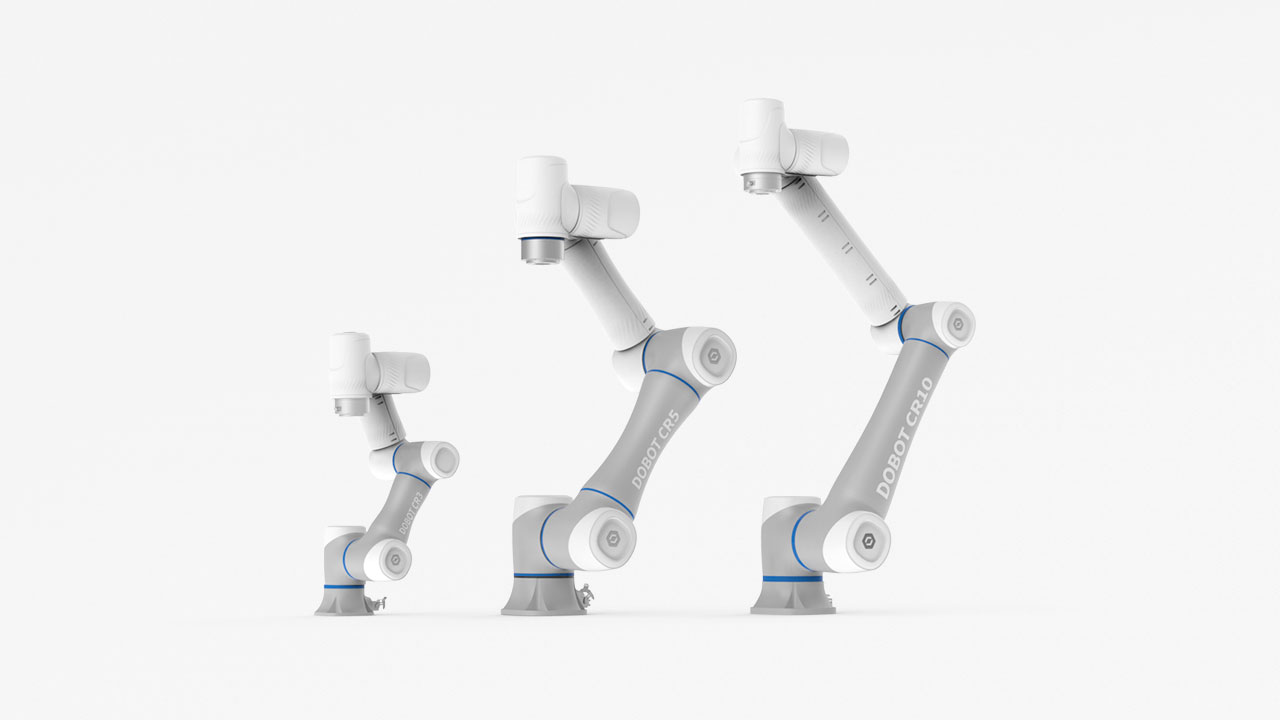

Types of Palletizing Robots

Robotic palletizers come in several forms, each suited to specific needs:

- Articulated Arms: These multi-jointed robots mimic human arm movements, offering versatility for complex stacking patterns. They’re ideal for diverse product types.

- Gantry Systems: Mounted on fixed tracks, gantry robots excel in high-speed, heavy-duty tasks, perfect for large-scale warehouses with consistent palletizing needs.

- Cobots (Collaborative Robots): Compact and human-friendly, cobots like those in our CRA Series work alongside workers in tight spaces, enhancing flexibility for smaller operations.

Key Features

Robotic palletizers bring unmatched benefits to the table:

- Precision and Speed: The CRA Series, for instance, achieves a 25% increase in the cycle time and unprecedented efficiency, ensuring flawless stacking at scale, far surpassing manual.

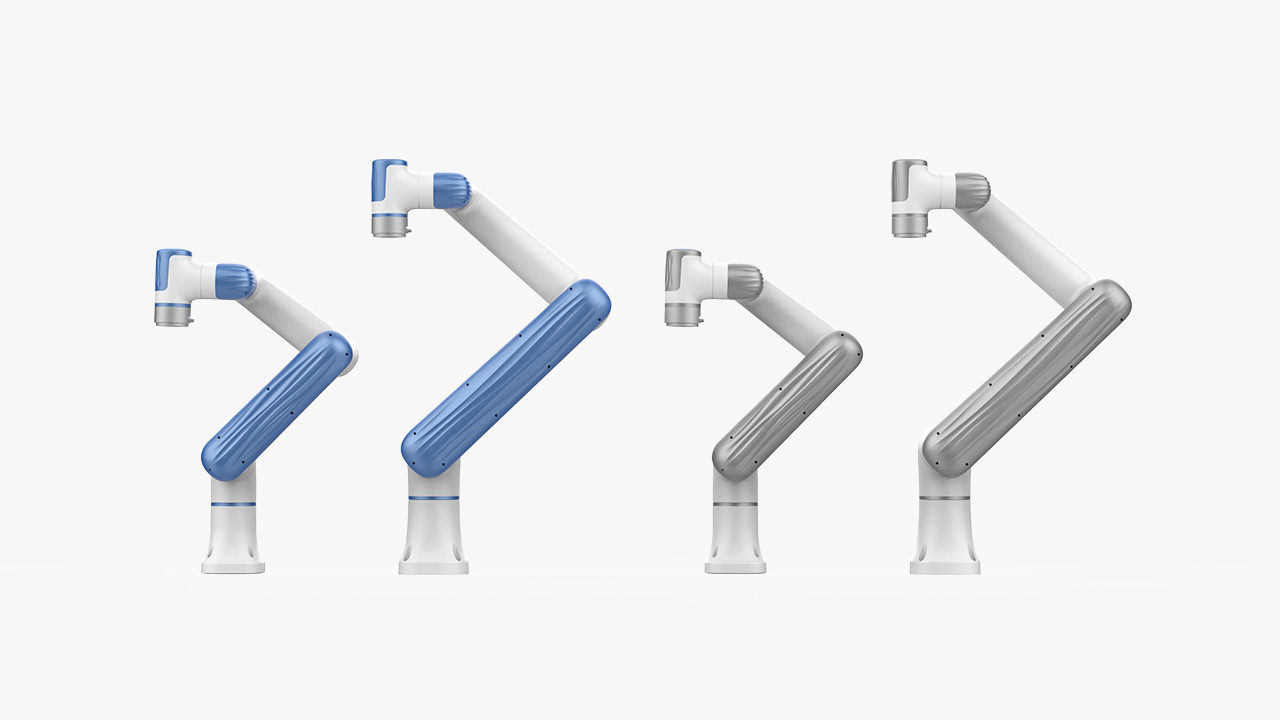

- Flexibility: With adaptable grippers, these robots handle everything from standard boxes to irregular shapes, seamlessly adjusting to your product mix.

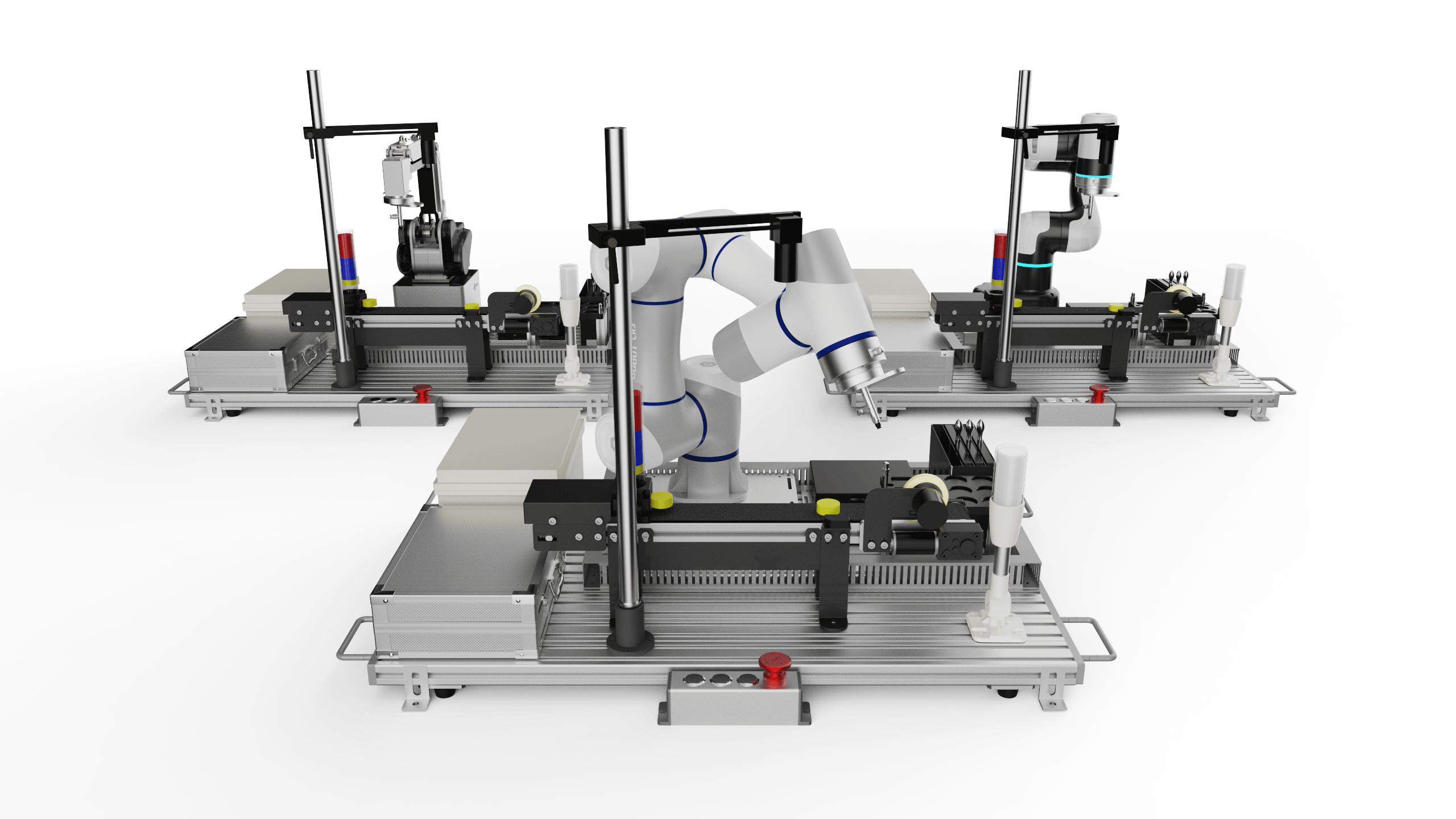

- Integration: These systems sync with IoT and warehouse management software, providing real-time data for smarter operations. You can monitor and optimize workflows on the fly.

DOBOT’s Solutions

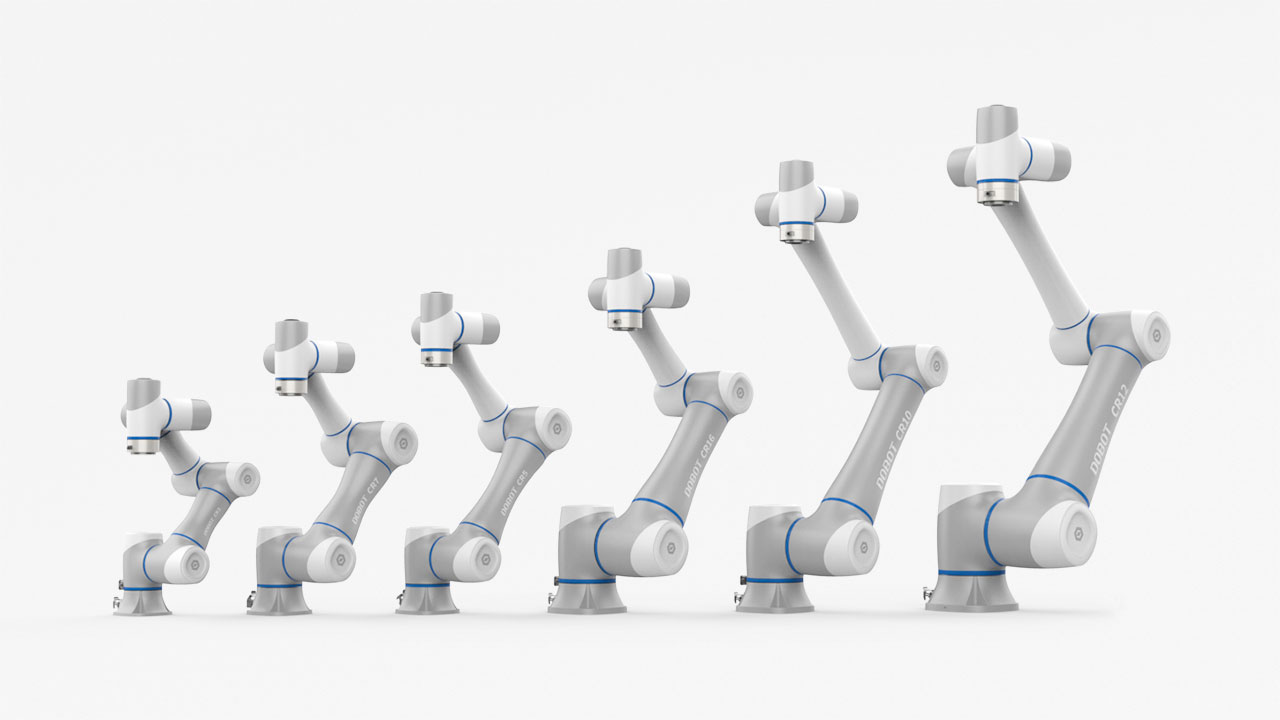

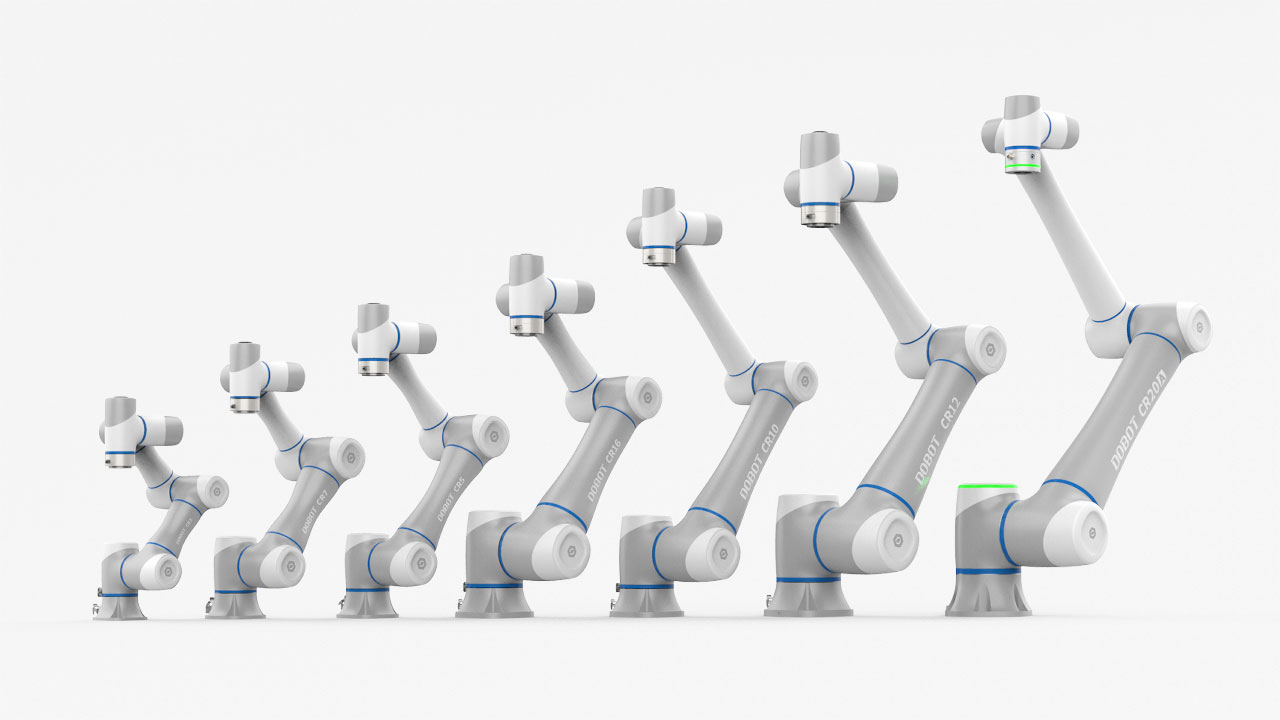

DOBOT leads the pack with its customizable palletizing systems, designed to meet diverse business needs. The CRA Series, for example, combines high-speed performance with compact designs, making it ideal for both industrial and commercial settings.

Whether you’re stacking heavy crates or delicate goods, our solutions adapt effortlessly, ensuring efficiency and growth. Curious about how they work? Explore our Customizable Palletizing Systems or watch their capabilities in action on our YouTube Channel.

Deciding between robotic and conventional palletizing requires evaluating their impact on key business factors like cost, scalability, space, safety, and customization. This comparison will help you choose the method that aligns with your operational goals, with DOBOT’s solutions highlighted as a leading option for automation in the United States.

Cost Analysis

Upfront Investment vs. Long-Term ROI: Conventional palletizing involves lower initial costs, relying on human labor and basic tools like forklifts or conveyors. Robotic systems, however, require a larger upfront investment for equipment, setup, and integration. Over time, robotic palletizers can offer significant savings by reducing labor expenses and boosting efficiency, often proving cost-effective for businesses with steady or growing demand. Our CRA Series, for example, is designed to optimize long-term value through consistent performance, in many cases achieving ROI in only 8 – 10 months.

Scalability and Space Requirements

Scalability: Robotic palletizers are built for high-volume, round-the-clock operations, effortlessly handling large workloads without adding staff. Conventional methods struggle to scale, as increasing output typically means hiring more workers, which raises costs and complexity. Our industrial robots support continuous operations, while their cobots provide flexibility for smaller or expanding businesses.

Space Requirements: Conventional setups, particularly those with specialized equipment, often demand significant warehouse space. Robotic systems vary—some require ample room, but our cobots are compact, fitting into smaller facilities, making them ideal for space-constrained environments.

Safety and Customization

Safety: Manual palletizing carries risks of repetitive strain and lifting injuries, common in labor-intensive settings. Robotic systems enhance safety by automating heavy tasks, reducing workplace hazards. DOBOT’s cobots, designed for human-robot collaboration, include safety features like sensors to ensure secure operations.

Customization: Conventional methods are less adaptable to irregular or varied products, often requiring uniform items for efficiency. Robotic palletizers, with flexible grippers, easily manage diverse shapes and sizes. Our solutions excel in customization, offering tailored setups for unique products, from delicate items to mixed product batches.

Some manufacturing systems, for example, require different modes of end-of-line operation. Palletizing can be customized for the system’s needs, even for different stacking styles.

By assessing these factors, you can select the palletizing method that drives your success. Our innovative systems make robotic palletizing a strong choice for efficiency and versatility.

Choosing between conventional and robotic palletizing depends on your business needs, budget, and growth plans. Here’s a clear guide to help you decide which method suits you, with our solutions as a standout option for automation.

When to Choose Conventional Methods

Conventional palletizing is ideal for small-scale operations with limited budgets or irregular workflows. If your business handles low volumes, such as a few dozen pallets daily, or lacks the capital for advanced equipment, manual or semi-automated methods using labor and basic tools like forklifts make sense. They’re simple to implement and require minimal upfront investment, fitting businesses with stable, low-output demands.

When to Invest in Robotic Systems

Robotic palletizing shines for high-volume, growth-focused operations or those handling complex products. If your warehouse processes large quantities daily, plans to scale, or deals with diverse or delicate items, robots offer unmatched efficiency and precision. Systems like the CRA Series streamline high-throughput tasks and adapt to varied needs, supporting long-term success.

DOBOT’s Deployment Ease

Transitioning to automation is straightforward with DOBOT. The CRA Series and cobots deploy quickly, minimizing downtime and integrating seamlessly into existing workflows. Explore how easy it is with our Deployment Guide.

Robotic palletizing outshines conventional methods in scalability, efficiency, and safety, making it ideal for businesses eyeing growth. While manual methods suit small-scale needs, robots like the CRA Series deliver precision and adaptability for high-volume or complex tasks. Automation reduces costs, enhances safety, and future-proofs your operations in a competitive U.S. market.

Ready to boost efficiency and stay ahead? Explore DOBOT Robotics to find cutting-edge palletizing solutions tailored to your needs. Act now—your future-ready warehouse awaits!