Imagine a factory where humans and robots work side by side, seamlessly blending precision with creativity. That’s the power of collaborative robots, or cobots—robotic arms designed to assist humans in tasks like assembly, welding, picking, and packing, enhancing safety and efficiency. Unlike traditional robots, cobots are intuitive, flexible, and safe for close human interaction, making them ideal for modern manufacturing.

Smart factories, the backbone of Industry 4.0, integrate IoT, AI, and automation to create adaptive, data-driven production environments. They optimize workflows, reduce downtime, and enable real-time decision-making. As you navigate this era, automation is critical. The industry has grown so popular in the modern era that the global cobot market is estimated to grow to $7.2 billion by 2030.

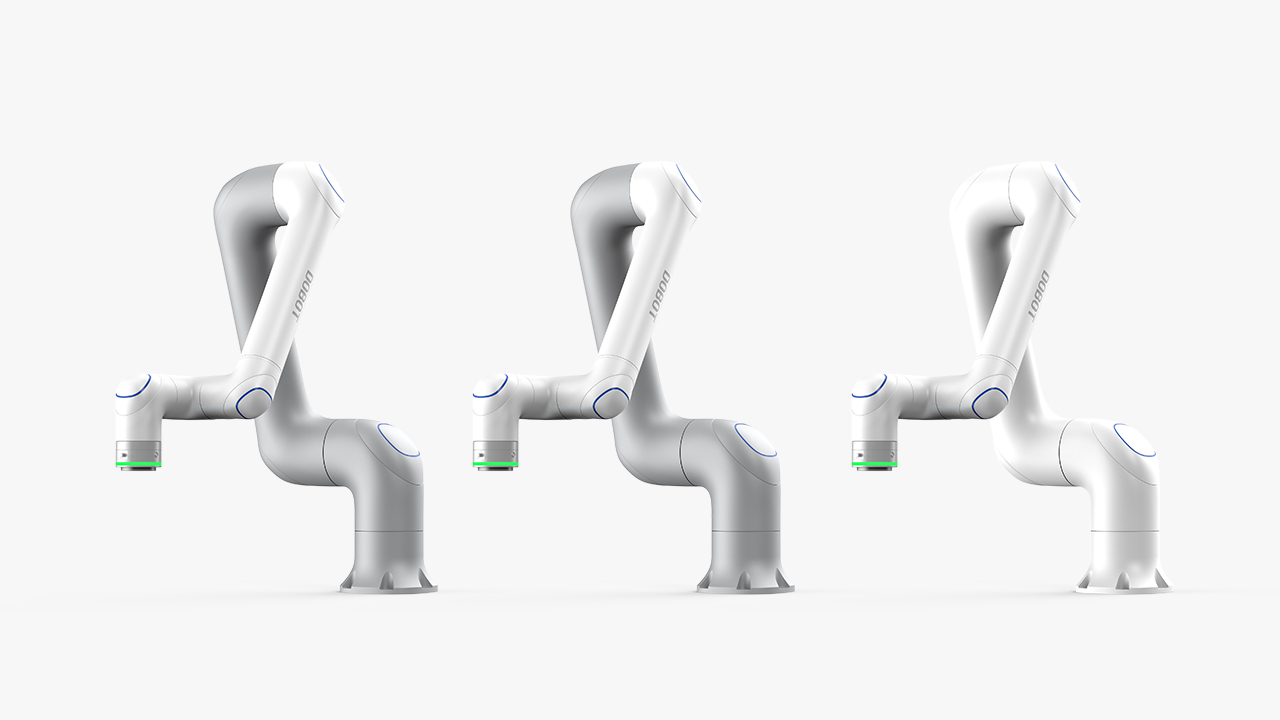

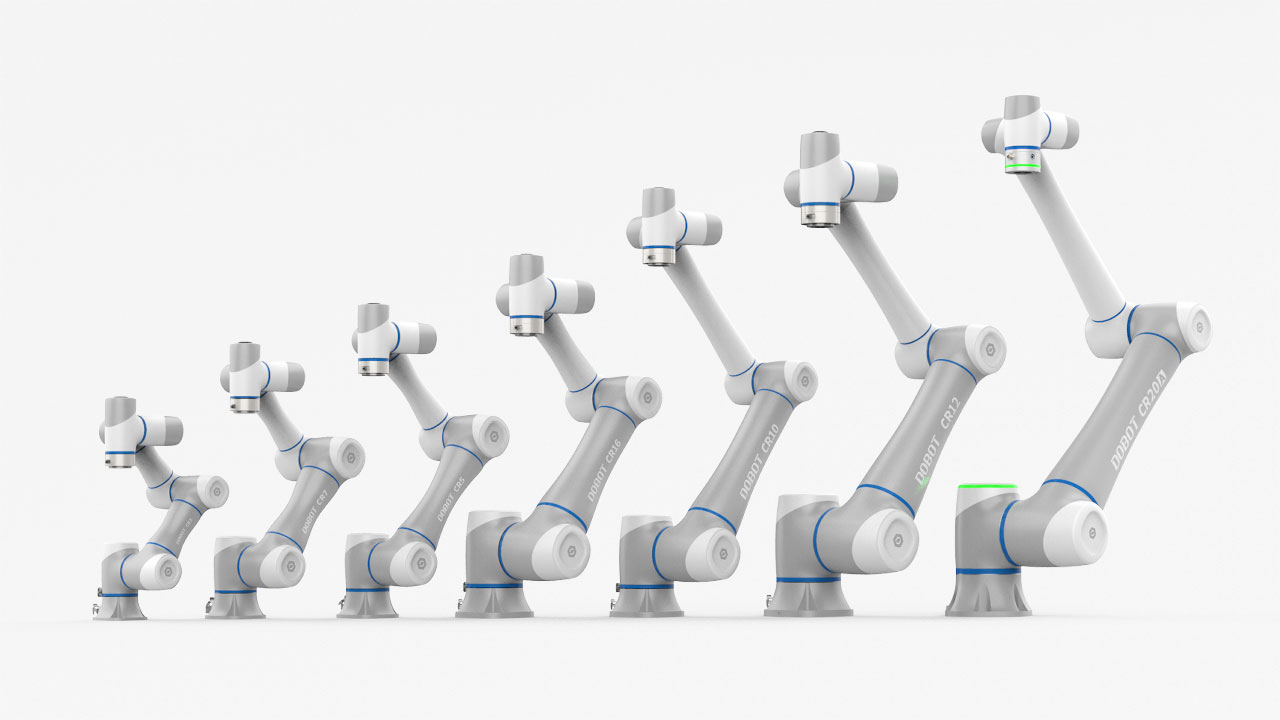

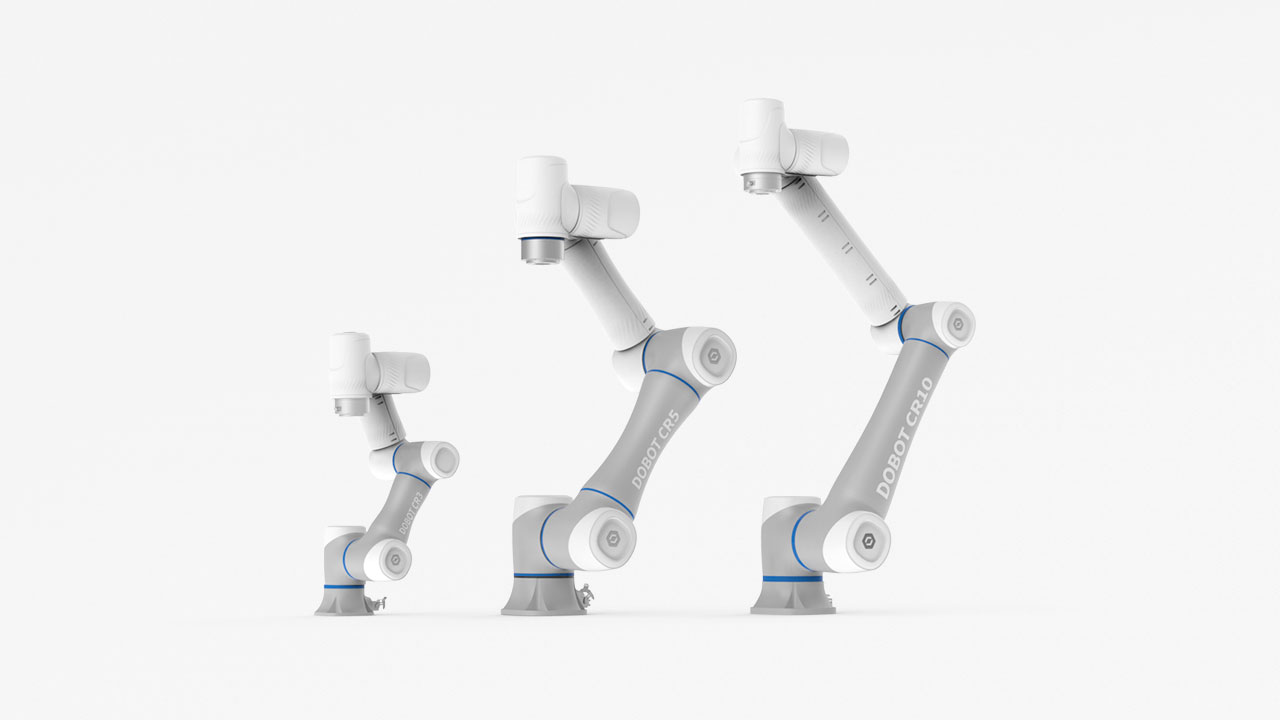

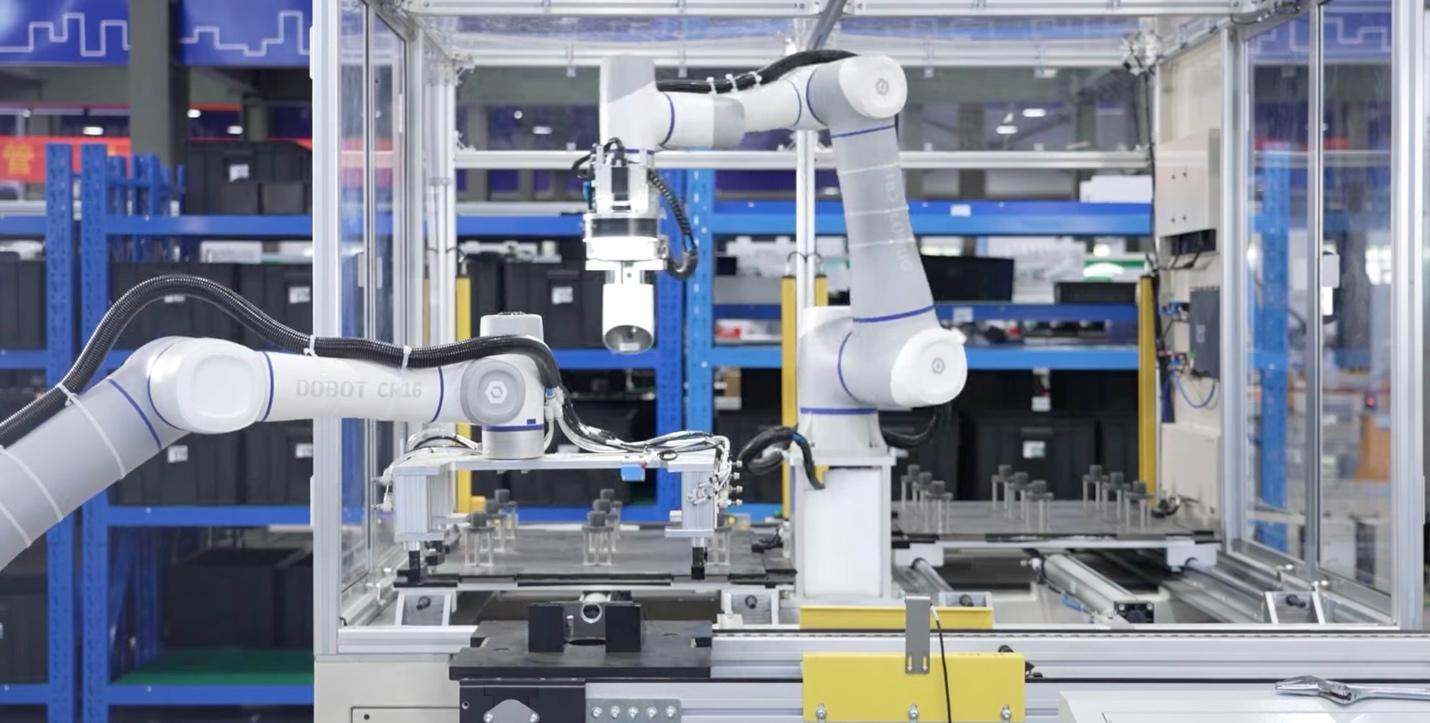

We’re witnessing a revolution where cobots, like the CRA Series, empower you to build smarter, more productive factories. Let’s explore how these collaborative robot applications are shaping the future.

Alt Tag: Cobot application

What are Collaborative Robots?

Collaborative robots, or cobots, are designed to work alongside humans in shared spaces, revolutionizing how we approach manufacturing. Unlike traditional industrial robots, which are often bulky, caged for safety, and rigid in function, cobots prioritize safety, ease of use, and flexibility. Equipped with advanced sensors and safety mechanisms, they detect human presence and adjust movements to prevent collisions, making them ideal for dynamic environments.

You can program cobots with intuitive interfaces, no coding expertise required, allowing rapid task adjustments. Their lightweight design and adaptability suit small-batch production and complex tasks, unlike traditional robots that demand significant setup. By combining human creativity with robotic precision, cobots enhance productivity in smart factories. As we explore their applications, you’ll see how their versatility drives innovation across industries.

Key Applications

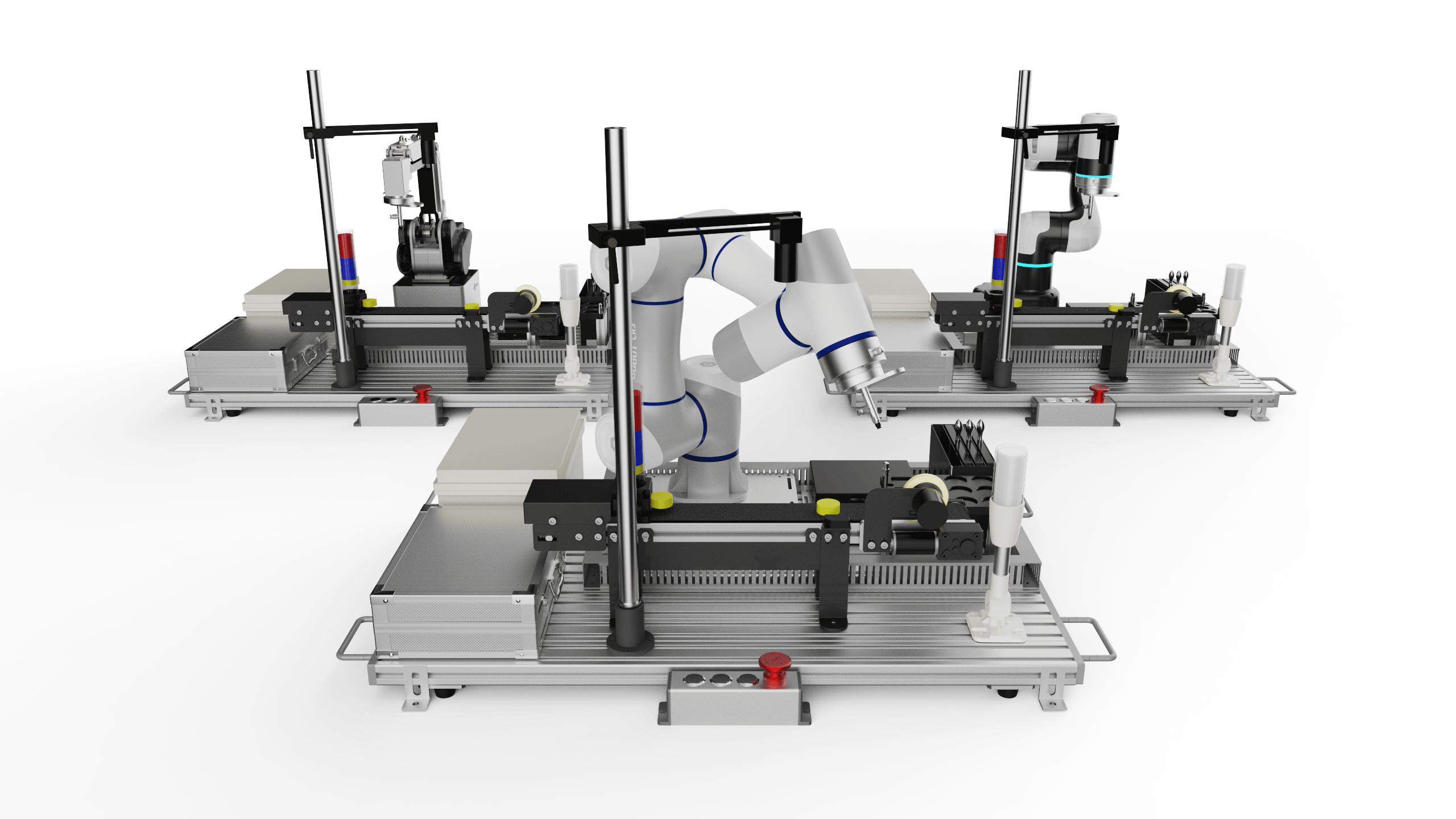

Cobots transform smart factories through diverse applications. In assembly, they streamline intricate tasks like electronics production, where they precisely place components, boosting speed without sacrificing accuracy.

For material handling, cobots automate repetitive tasks like picking and placing parts. DOBOT MG400, with its compact design, navigates tight spaces to transport materials efficiently, reducing worker strain.

In quality inspection, cobots enhance precision with integrated vision systems, scanning products for defects, and ensuring consistent standards.

For packaging, cobots optimize end-of-line processes; our flexible arms swiftly pack goods, adapting to various shapes and sizes.

These applications highlight how cobots’ versatility drives efficiency and scalability in smart factories, enabling you to meet production demands with ease.

Integration with Smart Technologies

Cobots excel in smart factories by integrating with advanced technologies for seamless connectivity and adaptability. Equipped with IoT capabilities, cobots collect real-time data on performance and production, enabling you to monitor workflows and optimize.

This connectivity supports predictive maintenance, reducing downtime. Machine learning enhances cobots’ capabilities, allowing adaptive processes — DOBOT’s AI-powered vision systems quickly identify surface defects and perform classification, improving tasks like quality inspection. By integrating with cloud platforms, cobots enable remote monitoring and data-driven decisions, aligning with Industry 4.0 goals.

These smart integrations make cobots not just tools but partners in innovation, helping you stay agile in fast-evolving markets.

Cobots are more than machines—they’re partners that free us to live more fully, unshackled from repetitive, tedious tasks. By automating the mundane, collaborative robots let you channel your energy into creative, meaningful work that sparks joy and purpose. In smart factories, cobots embody this humanistic vision, blending precision with empathy to elevate both productivity and human potential.

As we explore their benefits, you’ll see how cobots foster a workplace where innovation and wellbeing thrive, allowing you to focus on what truly matters.

Cobots transform manufacturing by boosting productivity and flexibility, liberating you from repetitive labor. With our cobots, tasks like assembly or material handling are streamlined, improving output without exhaustion.

Their intuitive programming means you don’t need to be a tech expert—our user-friendly software lets you reconfigure cobots for new tasks in minutes, adapting to shifting demands. This flexibility empowers small-batch production, perfect for dynamic markets. By automating monotonous tasks, cobots free you to tackle creative challenges, like designing innovative products or solving complex problems. Imagine focusing on ideas that inspire rather than repetitive procedures.

DOBOT’s versatility ensures your factory stays agile, letting you thrive in a fast-paced world while rediscovering the joy of meaningful work.

Cobots deliver unwavering precision, ensuring consistent quality while driving cost efficiency. DOBOT MG400, equipped with high-precision encoders, proprietary drives, and controllers, achieves a repeatability of ±0.05mm, making it perfect for delicate PCB welding tasks with pinpoint accuracy, reducing errors that plague manual work.

This reliability frees you from tedious checks, letting you upskill in areas like process optimization or innovation. While the initial investment in cobots is lower than traditional automation systems, the long-term savings are significant—reduced labor costs, fewer defects, and minimal downtime add up fast.

By automating repetitive tasks, we empower you to grow professionally, pursuing roles that ignite your passion. The result? A workplace where quality is assured, costs are controlled, and you’re free to explore your potential.

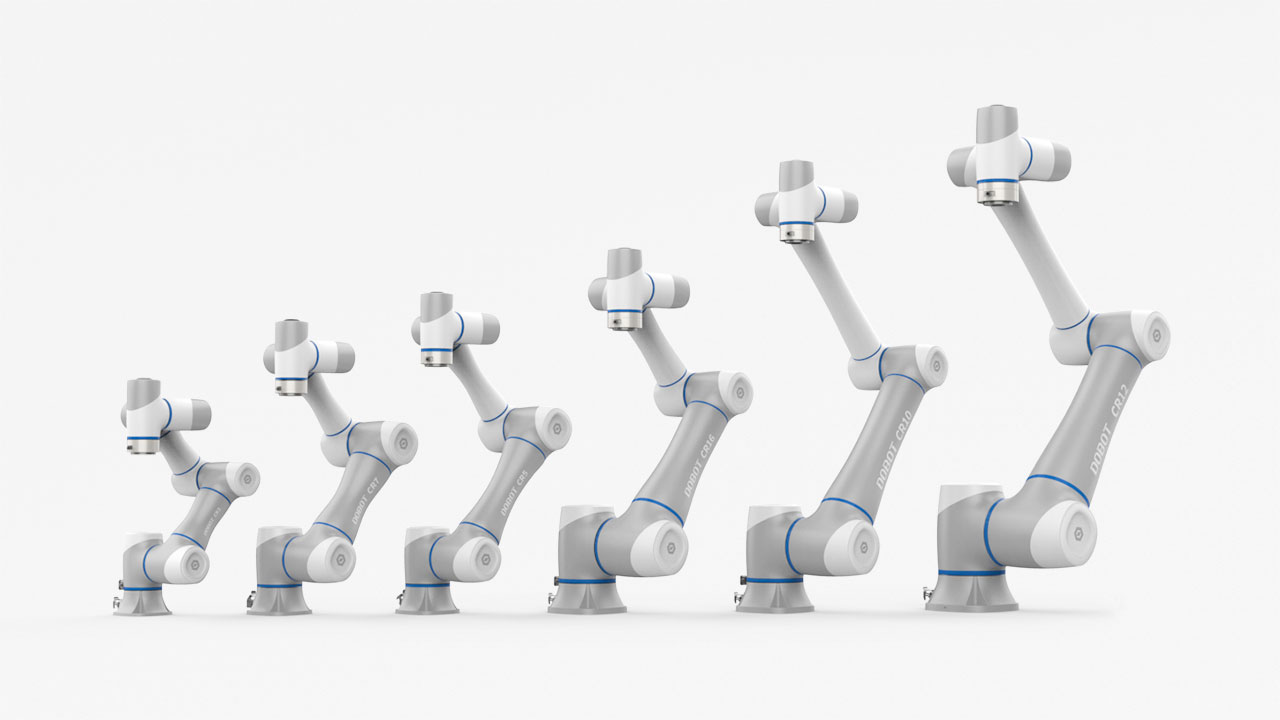

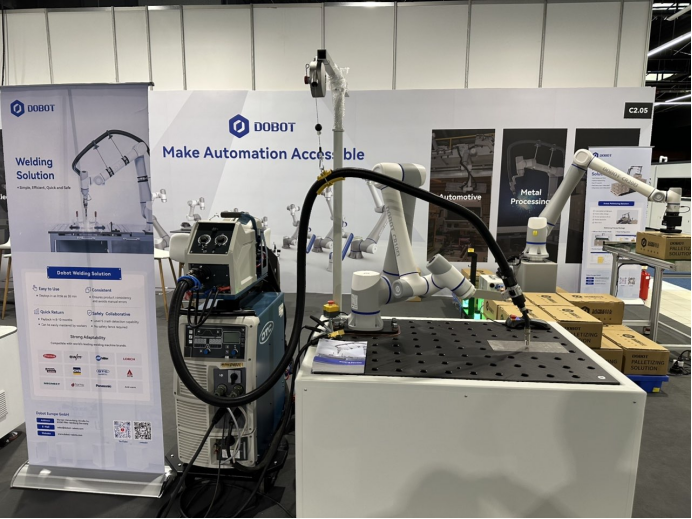

Cobots create safer workplaces, prioritizing your well-being by handling dangerous, repetitive tasks. Equipped with over 20 safety functions, the CRA Series detects human presence and slows or stops to prevent collisions, making shared spaces secure.

In smart factories, they can take on hazardous jobs, such as heavy lifting or working with sharp tools, which reduces workplace injuries and fatigue. This shift lets you focus on tasks that nurture your skills and spirit, fostering a sense of purpose. By automating grueling work, our cobots support a humanistic vision where technology enhances safety and dignity.

As automation grows, the safety features ensure you thrive in a workplace that’s both innovative and humane. Embrace a future where safety and creativity go hand in hand.

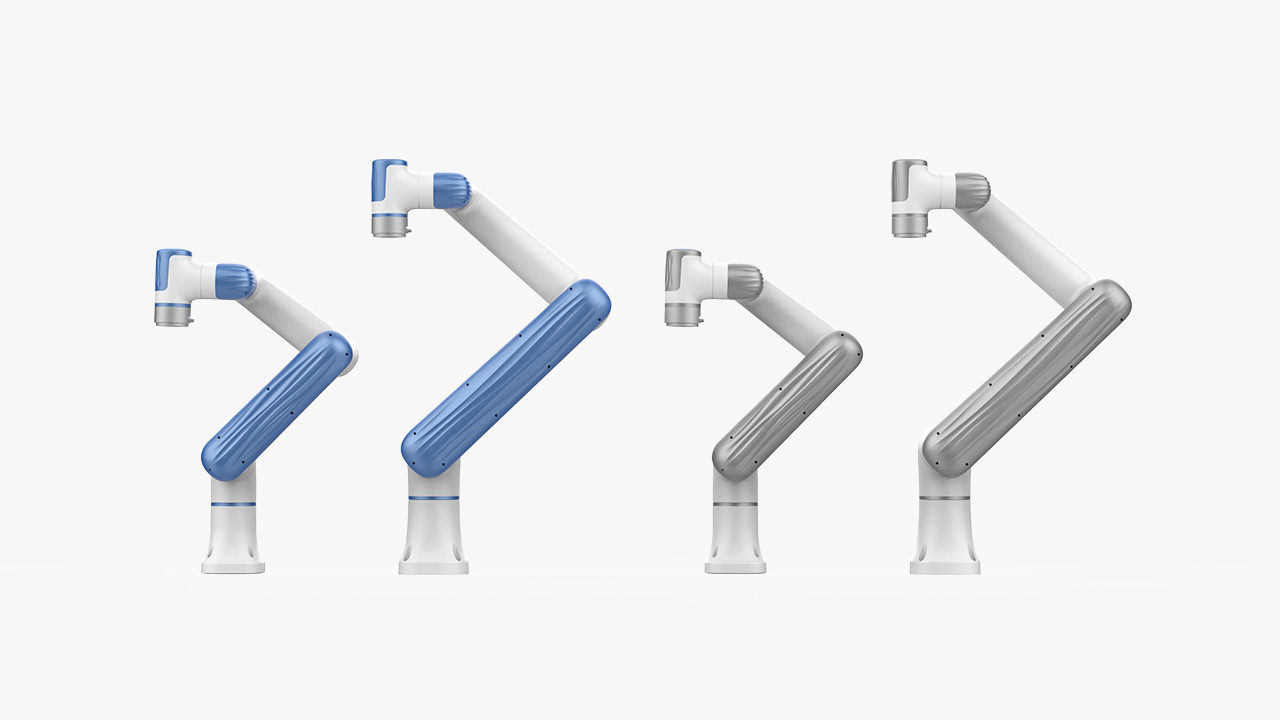

Alt Tag: Cobots make cobots

As Industry 4.0 reshapes manufacturing, collaborative robots are at the forefront, driving smarter, more connected factories. By integrating AI, IoT, and advanced human-robot interfaces, cobots align with Industry 4.0’s vision of digital transformation, enabling seamless data exchange and adaptive systems.

Cobots are likely to evolve to meet these trends, empowering innovation across industries while fostering collaboration between humans and machines.

AI-Powered Cobots

AI is revolutionizing cobots, enhancing their role in smart factories and other work environments. Machine learning enables cobots to analyze real-time data, optimizing tasks such as quality inspection with unmatched precision. Predictive capabilities, powered by AI, anticipate maintenance needs, minimizing downtime and boosting efficiency.

AI-powered systems can streamline workflows, making your production more agile and improving customer experience. Cobots will become smarter partners, helping you achieve operational excellence in an interconnected world.

Expansion into Other Industries

Cobots are expanding beyond manufacturing into healthcare, logistics, and more, supporting Industry 4.0’s cross-industry digital transformation.

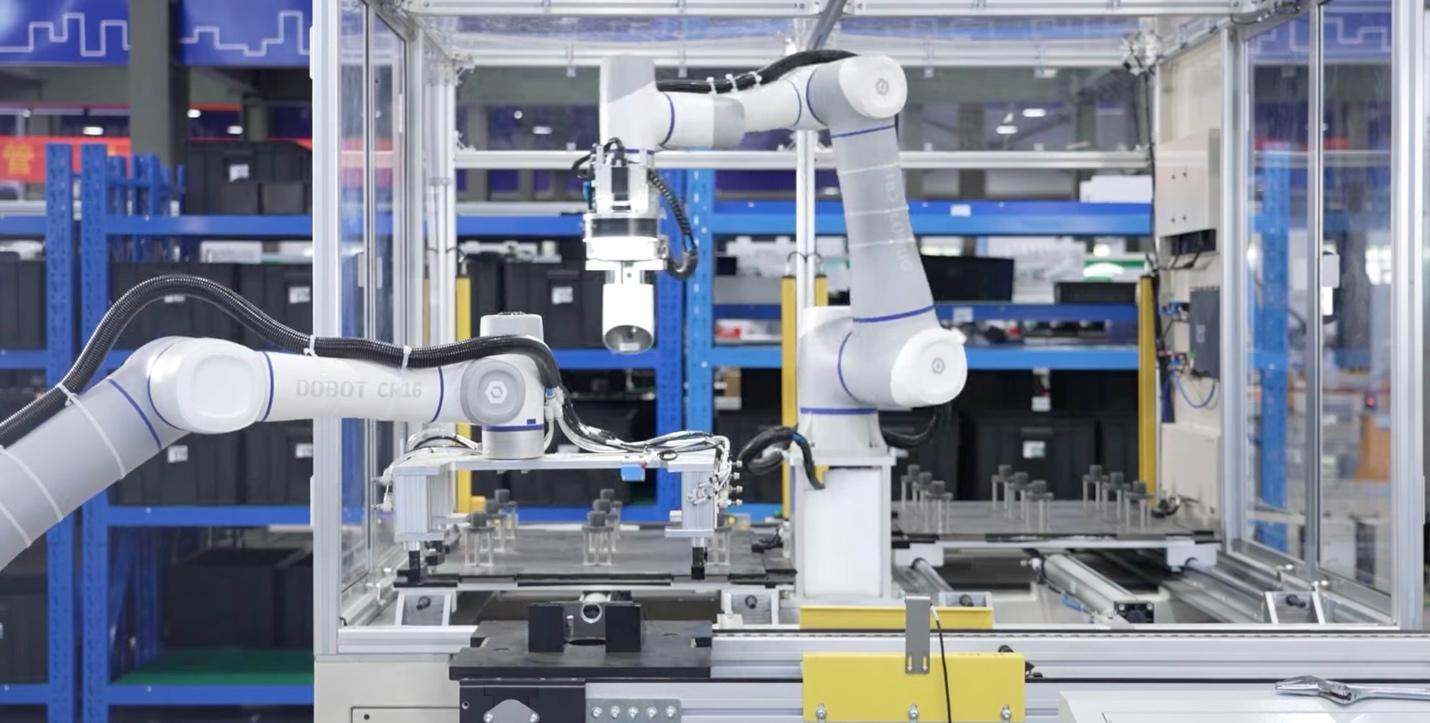

In healthcare, cobots assist with precise tasks like lab automation, enhancing efficiency. In logistics, cobots streamline warehousing by performing the heavy lifting. It can also be combined with lifting pillars to extend operating ranges.

You can adopt our versatile cobots to drive innovation, whether automating surgical support or supply chains. This expansion fosters smarter, more adaptive industries and safer workplaces.

Improvement in Human-Robot Interaction

Even with AI and Machine Learning, a human touch is necessary in nearly all fields. That being said, however, these incredible new technologies can make the human element of production and logistics far more efficient and effective. As humans and AI work side by side, we could see factories become more and more seamless in their processes.

As interactions improve, people will work more naturally alongside cobots, which will boost productivity and job satisfaction. Embrace a future where technology amplifies human potential in harmonious collaboration.

Collaborative robots are reshaping smart factories, blending precision with human ingenuity to drive smart factories forward. From assembly to quality inspection, cobots like CRA Series and MG400 enhance productivity, flexibility, and safety, freeing you from repetitive tasks to focus on creative, meaningful work.

Their integration with AI, IoT, and intuitive interfaces aligns with smart factories’ data-driven, adaptive ethos, ensuring consistent quality and cost efficiency. As cobots expand into healthcare and logistics, they’re paving the way for cross-industry transformation, fostering a future where human-machine collaboration thrives.

Looking ahead, the partnership between humans and machines will redefine industries. Cobots empower you to upskill, innovate, and lead in a world where technology amplifies human potential. By automating the mundane, our solutions let you explore new frontiers—designing groundbreaking products or solving complex challenges—while fostering workplaces that prioritize wellbeing and creativity. The future is collaborative, and you’re at its heart.

Ready to future-proof your operations? Explore our versatile cobots to unlock smarter, more human-centric manufacturing. Visit DOBOT’s Solutions today and take the first step toward a transformative partnership.