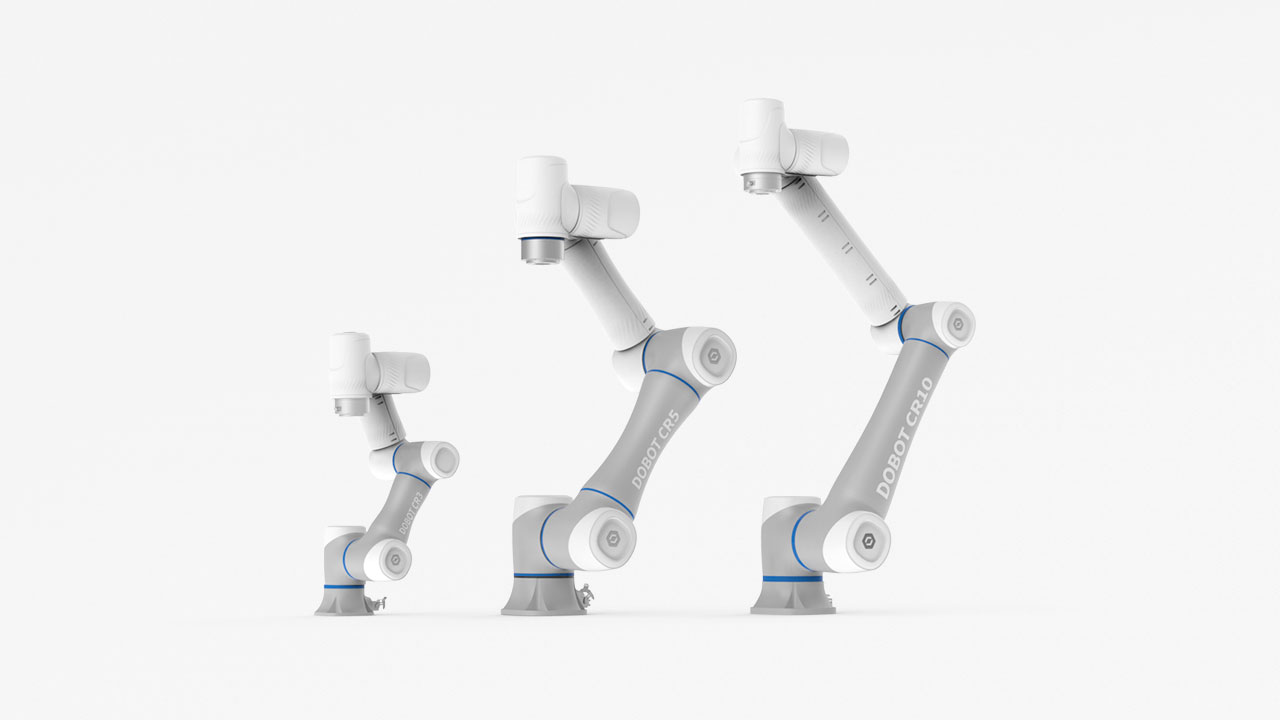

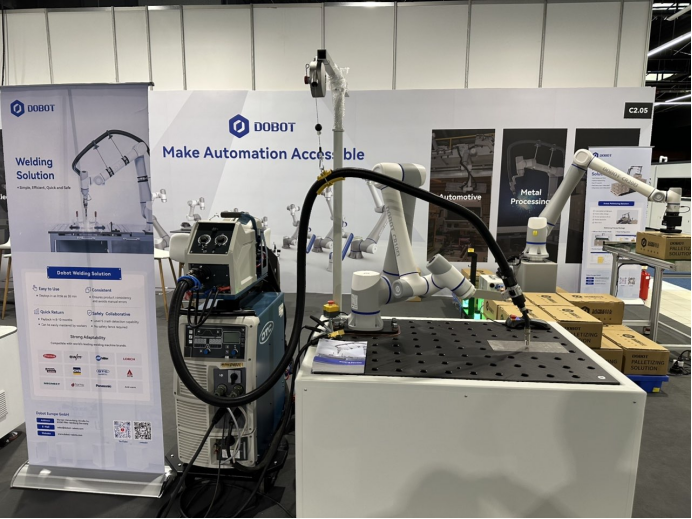

Over the last decade, we have seen cobots moving beyond the low-hanging fruit of machine tending and material handling. Cobots nowadays are built to work safely with humans becoming increasingly popular for vast application-specific solutions.

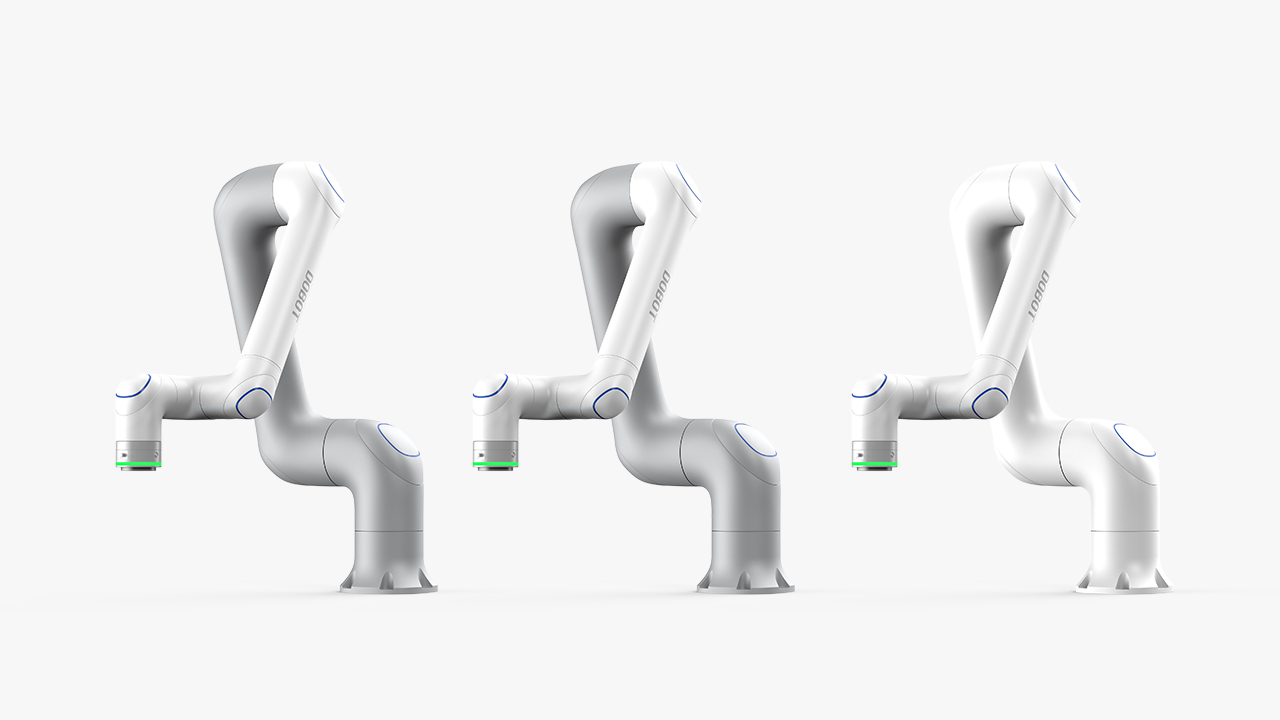

DOBOT CR5 collaborative robot simplifies programming and controls methods, making it even easier for operators with no programming experience to deploy and set up. Users integrate DOBOT CR5 with a variety of vision modules, end effectors, sensors, and other peripheral tools. The versatile 6-axis robot will excel in your desired applications.

Discover the diversity of the following applications and identify how DOBOT CR5 distinguishes itself from other cobots and comes out as one of the best picks for cost-effective robotic arms.

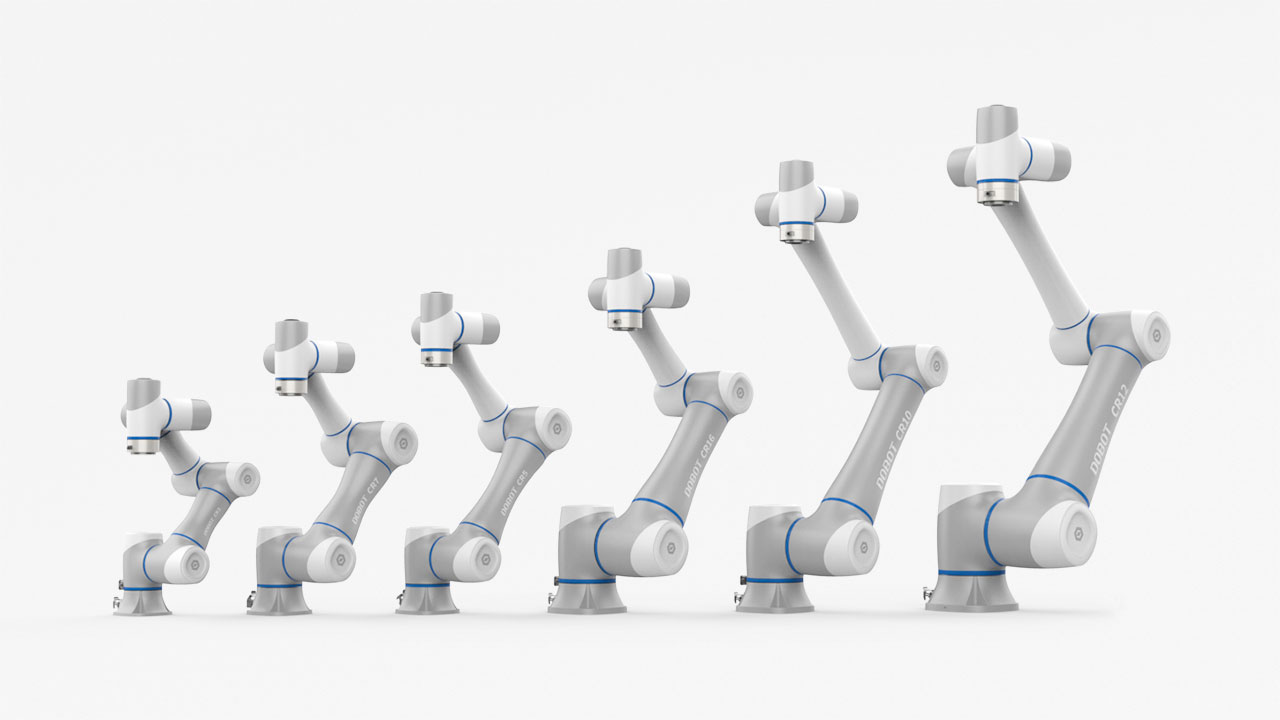

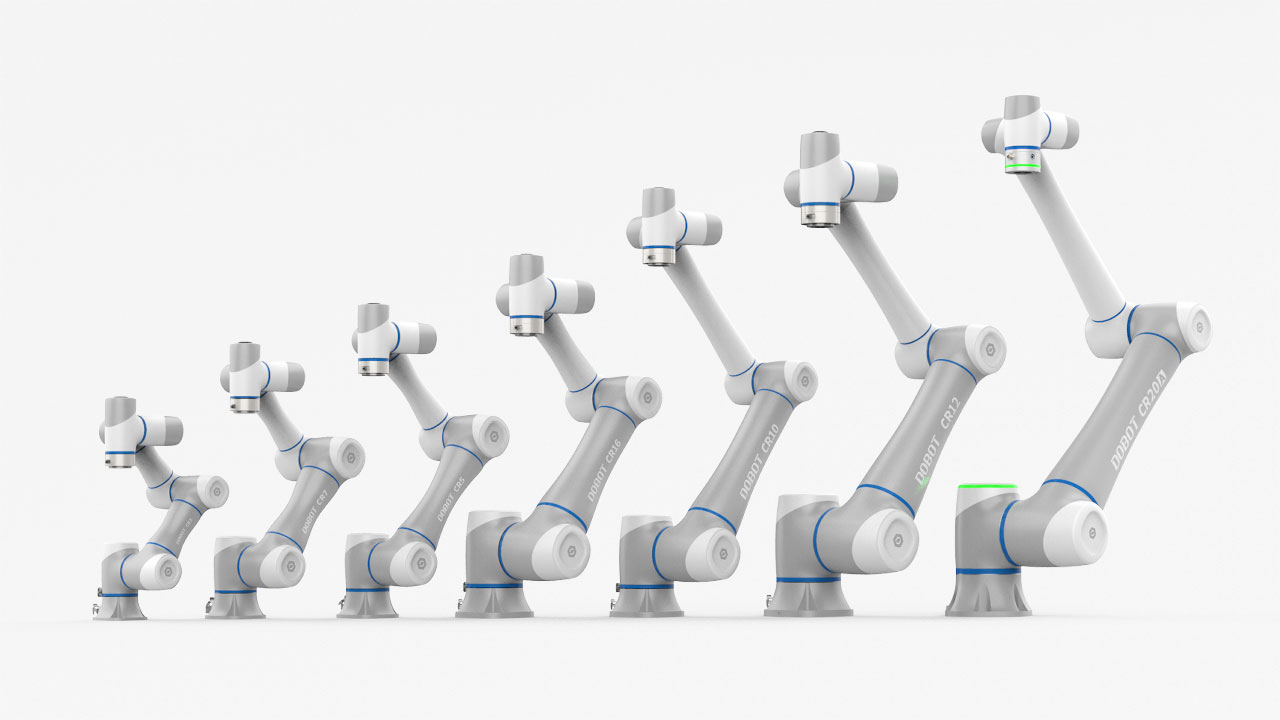

Benefits of DOBOT CR5 Collaborative Robot Compared to Other Cobots

Easy to Use

- teaching by demonstration: teaches the robot a new task by simply moving it through the pathway to the correct position and with a touch of a button

- easy programming: support visual, drag & drop, and block-based programming language, including Blockly

- multiple control methods: support Wi-Fi connection, apps on iPads and tablets as well as a teaching pendant

Safe to Work Alongside

- Multiple protections: camera entry detection; real-time obstacle avoidance with every-5ms dynamic monitoring, 10cm-proximity pre-touch sensing & online route planning

Wide Compatibility

- works with mainstream end-effectors and accessories; supports chip implantation like Google TPU2 and TensorFlow chips for feature extraction, pattern matching, and model training.

Applications of DOBOT CR5

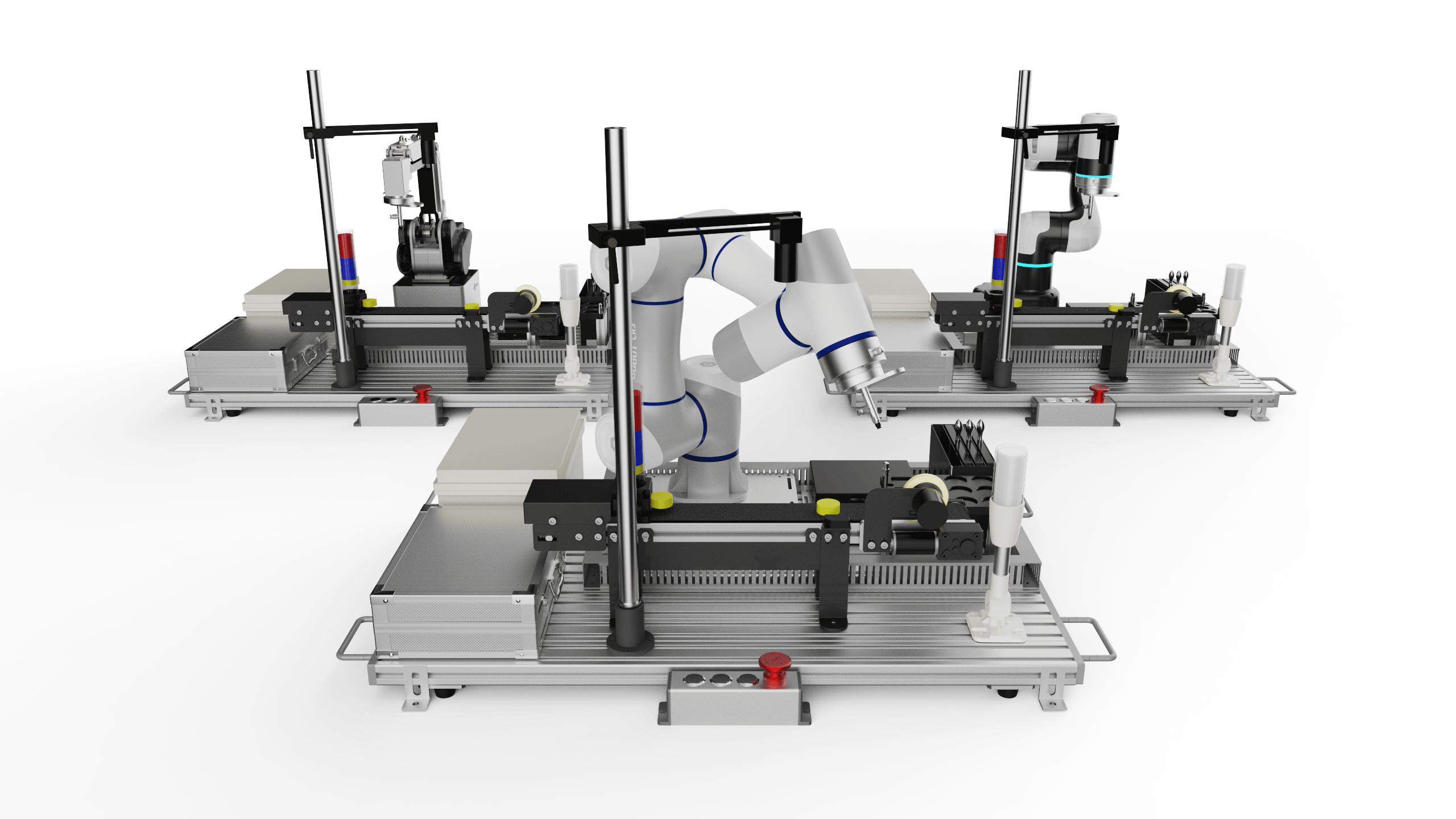

Pick & Place

CR5 pick and place

Manual pick-and-place is one of the most repetitive tasks performed by human workers today. The mundane nature of the task can often lead to mistakes or injuries. Pick and place applications are a good start for first-time cobot users.

Users should install a gripper or a vacuum cup effector on DOBOT CR5 and the robot can pick up already packaged products or sort things, such as components from a tray or conveyor as long as being integrated with advanced vision systems. DOBOT CR5 supports teaching by demonstration, so users teach the robot a simple pick and place program just in a few minutes. This technology clears the roadblock for job shops to implement simple robotic automation tasks, such as pick and place, material handling, etc.

Sanding & Polishing

Traditional manual sanding comes with constraints, hardships, and dangers, which could slow the manufacturing process and make it more expensive. DOBOT CR5 can “see” and “feel” with vision and force sensing that improves the overall economics of using them. Being able to sense contact pressure is the Dobot robotic arms' advantage, as they are adaptable to various surfaces, part variations, dimensions, locations, and materials.

Screw Driving

DOBOT CR5 saves costs and brings quality benefits through useful features, such as adjustable speed control, multiple I/O options for integration with PLC, and other line control techniques. DOBOT CR5 picks a screw from the screw feeder machine, follows the workpiece on the conveyor belt, and drives the screw into the workpiece before automatically determining whether the screw has been driven securely according to the preset torque.

During the working process, operators do not need to stop the conveyor belt, which helps boost efficiency and productivity. The force-sensing technology enables DOBOT CR5 to work with different electric screwdrivers and make it easier and more cost-effective to automate screw driving tasks.

Wire Harness Testing

Cable harnesses in modern electronics are becoming more complicated and diversified, bringing challenges in testing various cable harnesses in production. Manual testing includes long testing time, risk concerns to operators, subjective criteria for pass/failure tests, and testing variants by different operators.

The biggest concern to automating this process is the flexibility for different cable harnesses. One cable harness may differ from another in terms of the configuration of wires or the connection interface.

The DOBOT CR5 automatically locates the connector, adjusts the robot's gripping posture in real-time based on force perception technology, and then inserts and plugs in a flexible manner. The robotic arm can be integrated with the Manufacturing Execution System (MES) to keep records and upload test results.