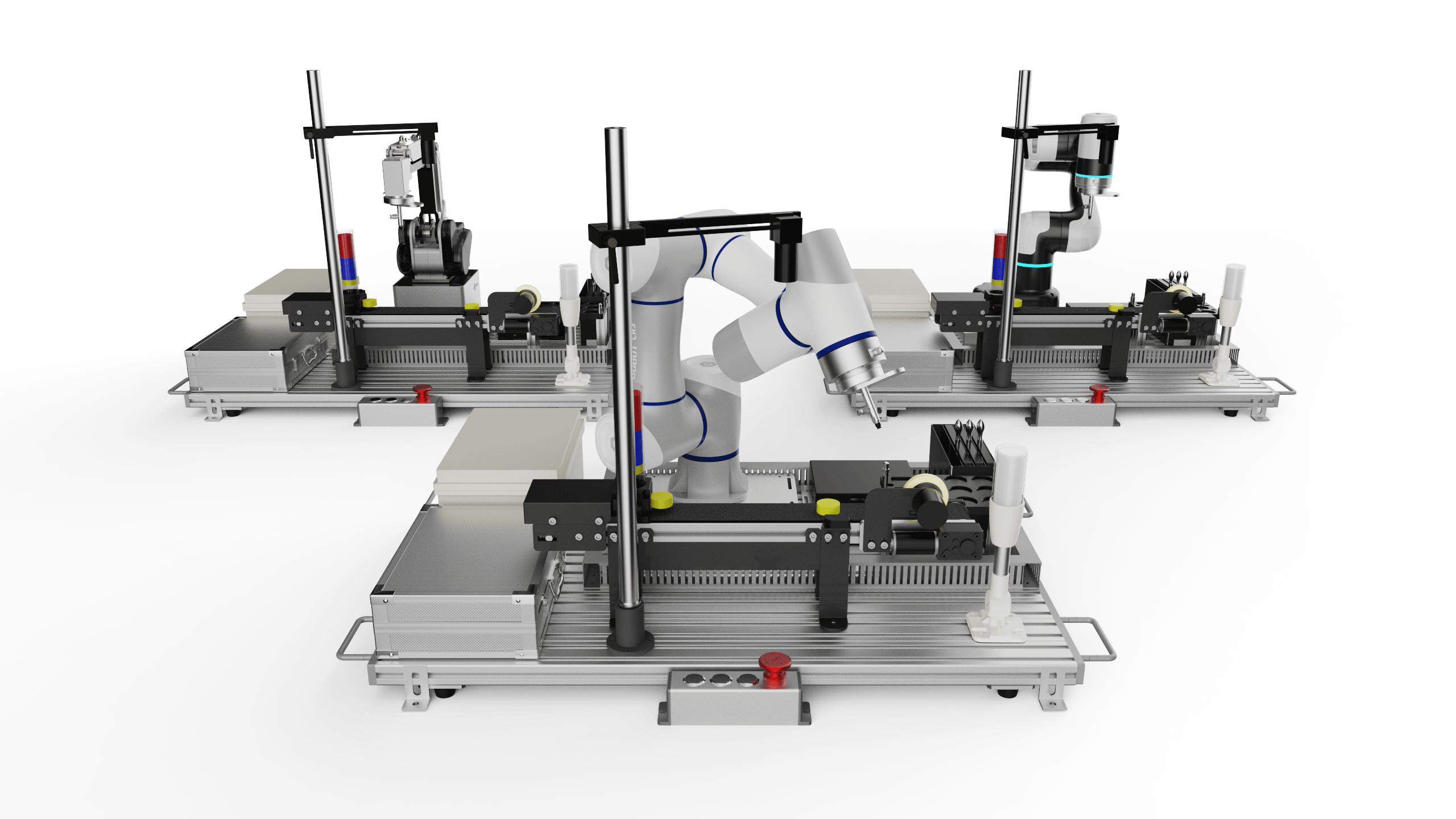

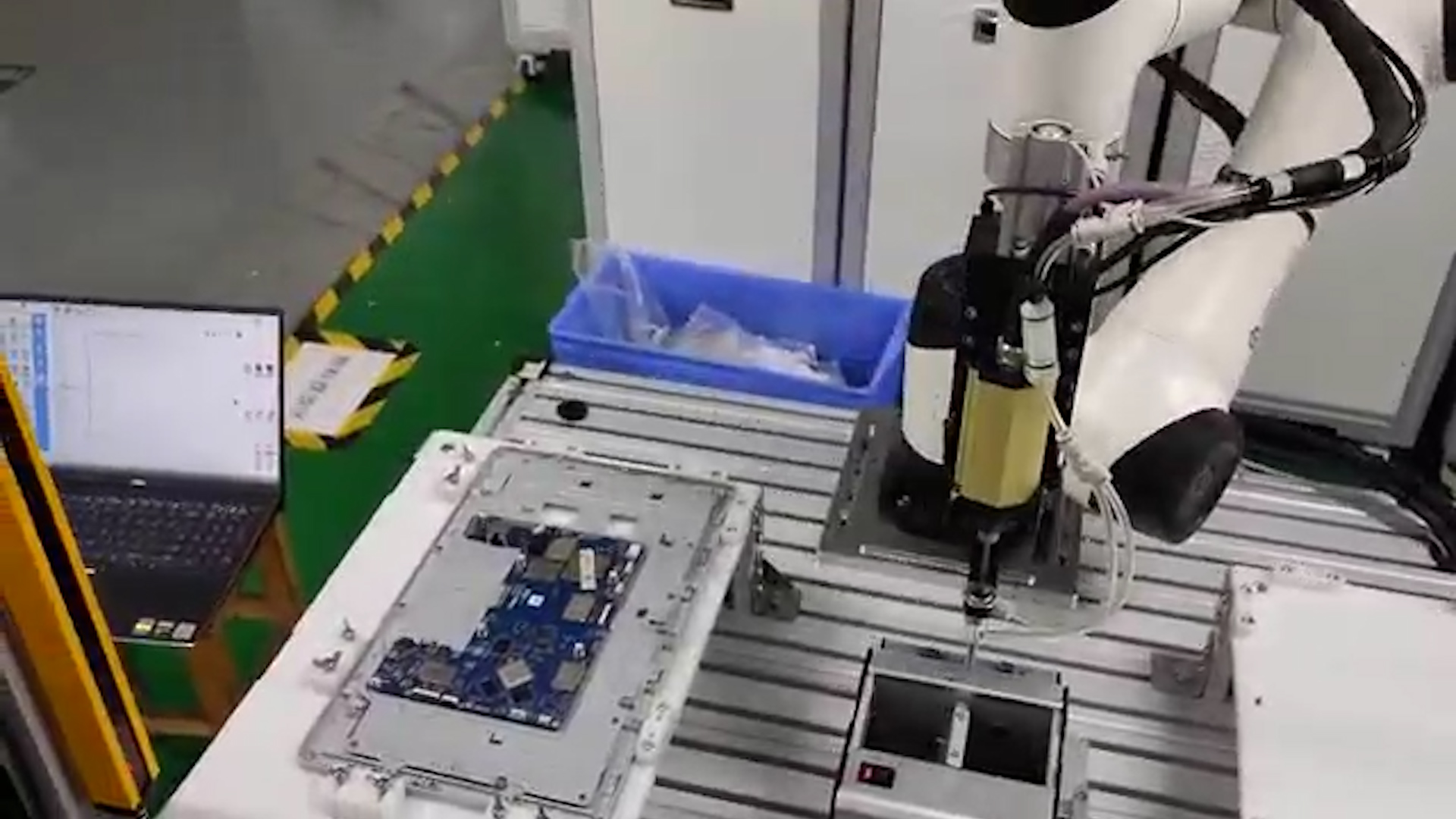

Dobot has developed a collaborative robot screwdriving process package that does not require programming skills suitable for smart electric batches. It perfectly combines intelligent robot operation with innovative locking technology, which can accurately lock and attach M1.0-M10.0 screws.

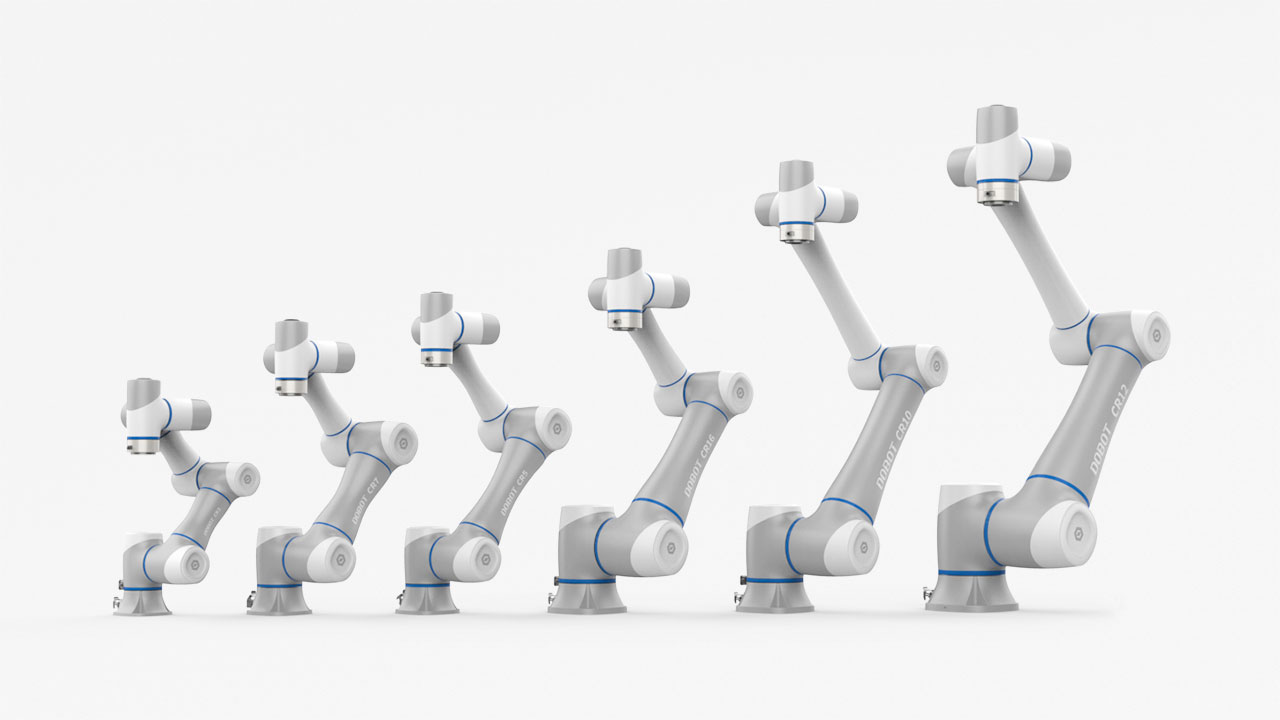

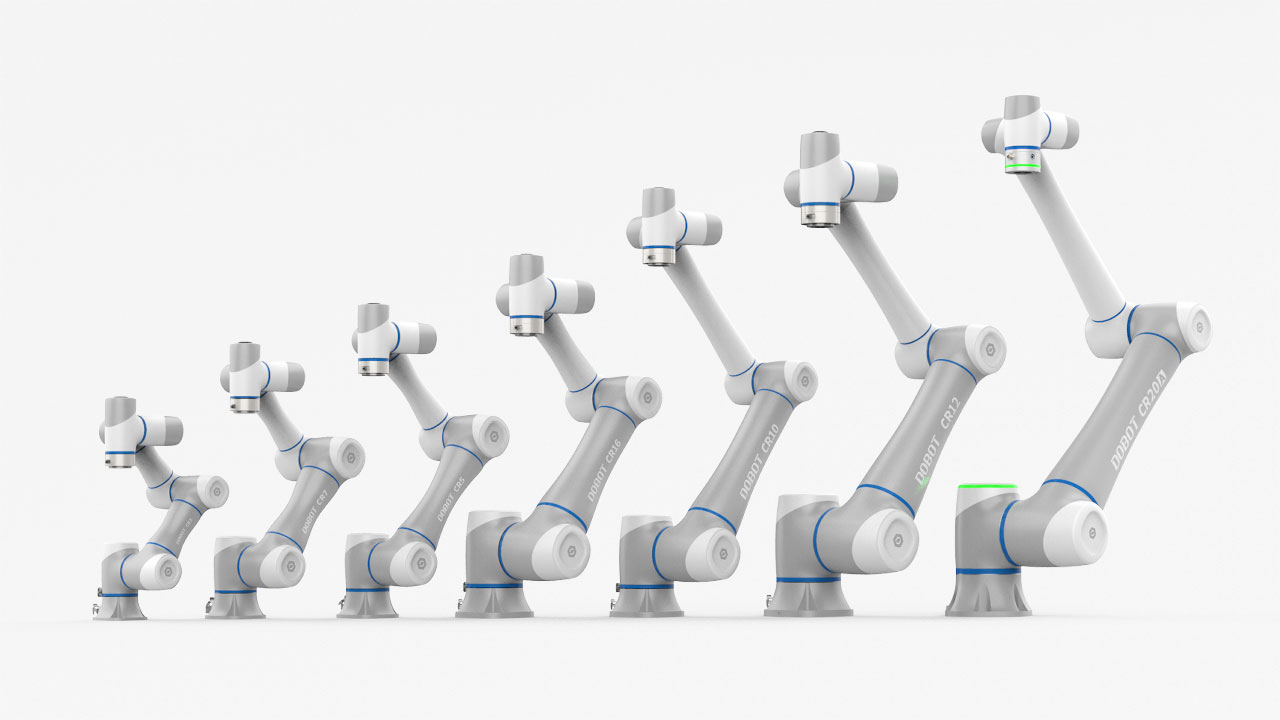

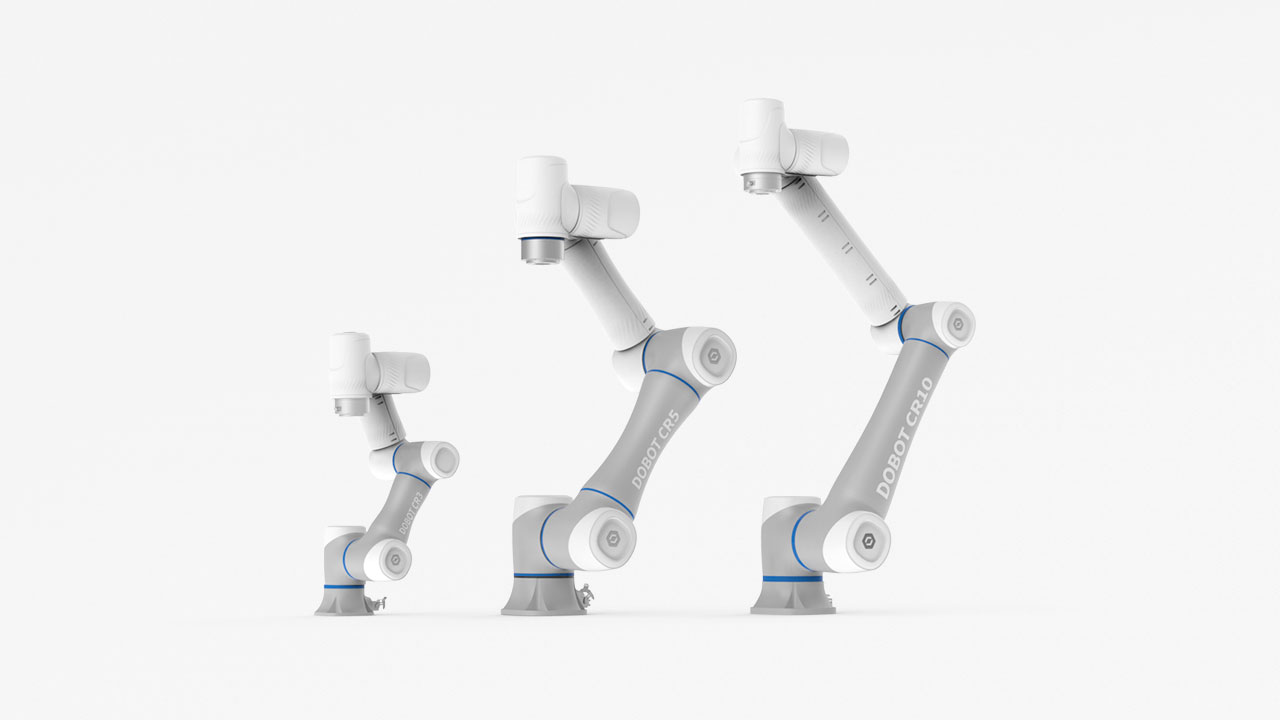

This solution supports multi-angle and multi-posture locking screws to meet the diverse needs of fast production changes in small-batch personalized customization mode. The working range of the CR series collaborative robot covers 620-1700 mm, enabling a 360-degree all-around screwdriving flexible solution.

The Dobot collaborative robots use industry-leading independent technologies, such as vibration suppression and full-parameter calibration, to achieve a high-speed, stable operation and precise positioning in complex attitude operating environments. It meets the standards of international certifications such as CE, NRTL, CR, ISO 13849, ISO/TS 15066, and others, significantly improving the reliability and safety of the screw locking automated solution.

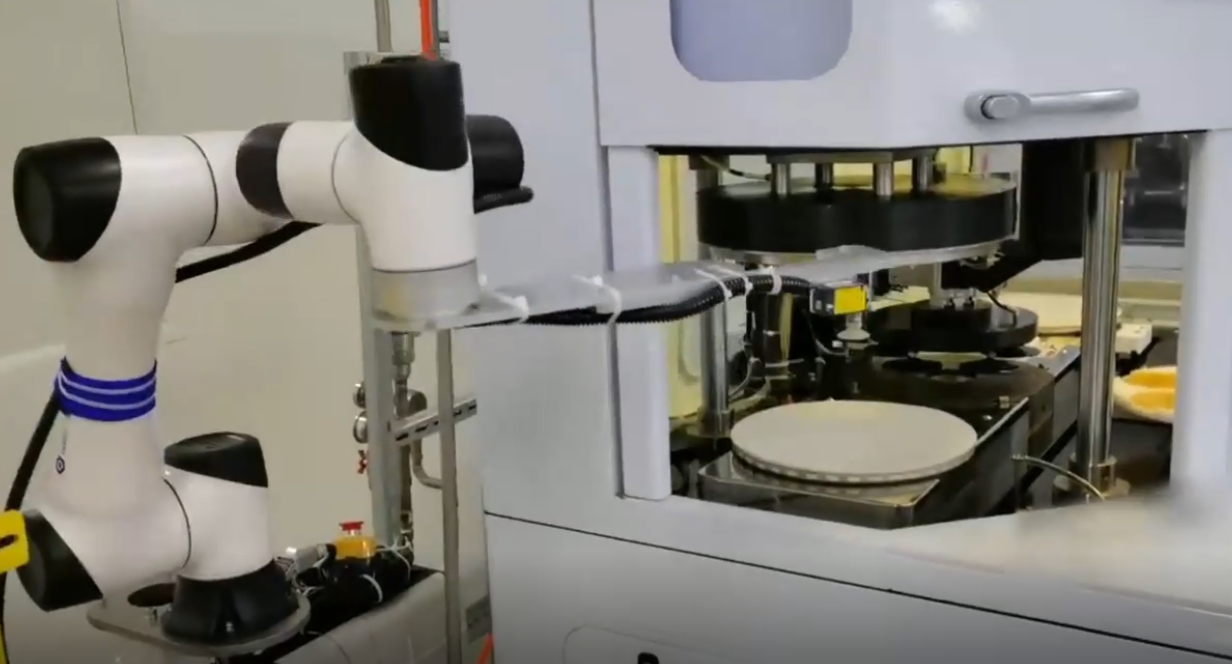

.00_00_06_20.Still001.jpg)